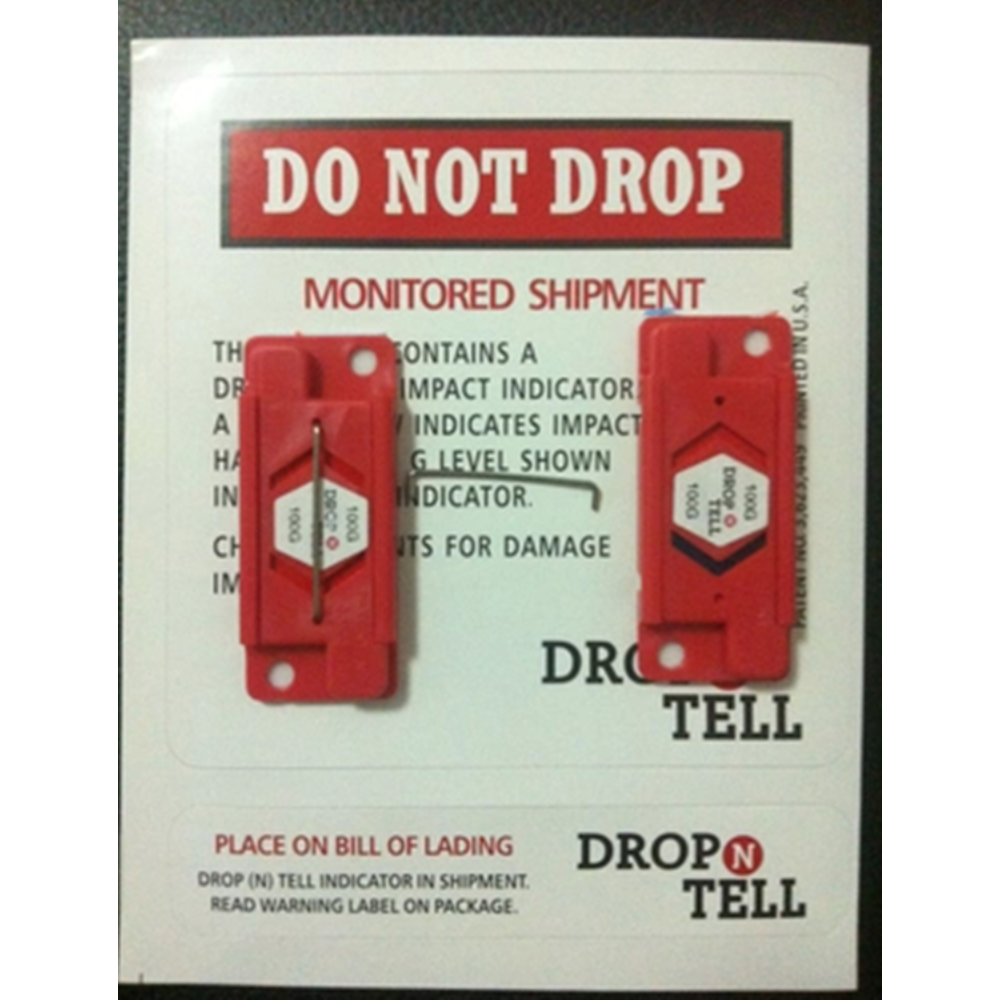

DROP N TELL Shock Label Imported From USA

Liên hệ

Drop N Tell shockproof labels are used to attach to the outer carton of the package. When the goods are impacted or vibrated by external forces, the “” or “” arrow in the middle changes from red to blue to remind the consignee or handler that the goods have been impacted in some way. a certain level and must be carefully examined.

What Is DROP N TELL Label?

” Anti-Shock Label (DROP N TELL) “ is a precision vibration monitoring device that can sense and display the vibration level and it is a non-magnetic product with mechanical structure.

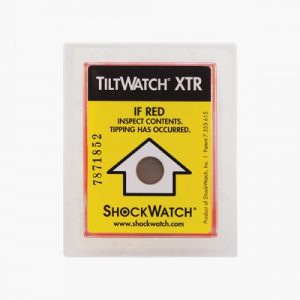

If a crate, wooden crate, or container with “shock absorber” is subjected to severe vibration or impact, the arrow will turn RED to indicate that excessive impact has occurred.

If wooden crates, wooden pallets, or containers with “shockproof stickers” are shaken or impacted strongly, the tip will become numb.

Normal movement or bumps on the road will not affect the “shock absorber”. Unless it is subjected to vibrations other than the vibration level set by itself. Then it will react.

” Anti-shock sticker (DROP N TELL) “ adopts high viscosity mixture and all components are not affected by humidity and normal temperature. Once the “anti-shock sticker” reacts, it will not be restored.

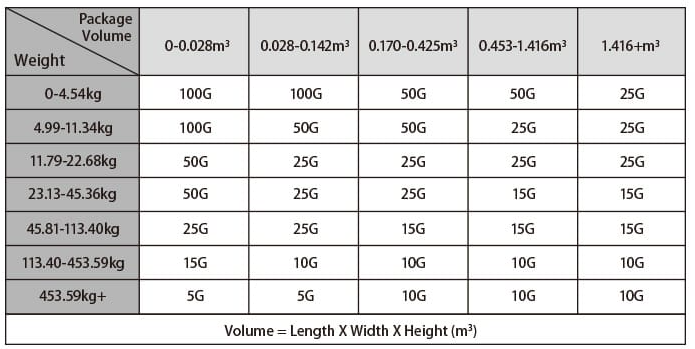

Comparison table of reaction intensity of each type of shockproof label (DROP N TELL)

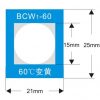

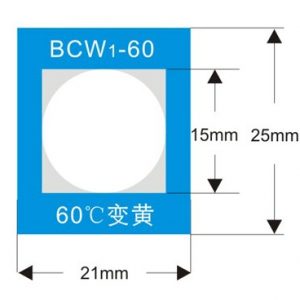

Specifications (label size not less than 52mm × 21mm)

Different specifications of “Shock Resistant Label (DROP N TELL)” can be used to distinguish the size of the impact force.

For example, 6 product specifications are provided, which are 5G, 10G, 15G, 25G, 50G and 100G.

Different specifications indicate the difference in external impact force of the trigger label, divided by the strength of the sensitivity, 5G is the most sensitive, 100G is the least sensitive, and the order is 5G, 10G, 15G, 25G, 50G, 100G.

Its activation strength is marked on the top and bottom of the front of the label. These mechanical label changes indicate that when the packaging box is impacted on a certain flat surface, the packaging cannot effectively protect the product.

The technical manual can select the appropriate type of impact resistant label for the product.

Selection Rules

The choice of shockproof labels depends on the volume (length × width × height) of the goods and the weight of the goods: the larger the volume, the heavier the goods, the more sensitive the type.

Other internal factors also need to be considered:

- Packaging materials: The packaging design is quite stable, the lower the damage rate, the lower sensitivity can be selected.

- Fineness of goods: If the goods are very fragile and have high transportation requirements, then choose sensitive type.

- Product protection point and focus: When designing special products, such as heavy goods, the transportation requirements are relatively high. Therefore, it is recommended to choose a type with high sensitivity.

How to Use DROP N TELL Shockproof Labels

Each set of shockproof stickers includes three parts: shockproof sticker, warning sticker and small sticker on the bill of lading.

The small bill of lading label must be affixed to the shipping document to indicate to the shipping company and the consignee that a “shockproof label” has been affixed to the goods being shipped.

A small sticker on the bill of lading must be affixed to the shipping document to ensure that the shipping company and the consignee are aware that a “shockproof label” has been affixed to the goods being shipped.

The “shockproof label” itself can be affixed to the outside or inside of the shipped goods.

Each shockproof label can peel off the back paper and stick it on the goods to be transported, or fix the goods to be transported with two 6/32 “iron nails, arrow direction on” shock – Shockproof labels should be the most transported goods.

Direction prone to vibration. Can attach “Anti-shock label” to the transported goods, then pull out the small iron wire used to fix it, then the “anti-shock label” “will be activated, and check the vibration of the goods.

Because the DROP N TELL anti-shock label is a one-time use product, because you must pay attention to the small iron wire before completely pasting it on the goods, so as to avoid incorrect product activation.

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@sancopack.com.vn