Preservation of goods

Fast Cooling System For Fruits: Optimal Storage Solutions

In the agricultural export industry, especially fresh fruit, maintaining quality after harvest is an important factor in increasing product value and extending shelf life. The rapid cooling system is the optimal solution to quickly reduce fruit temperature immediately after harvest, limiting the growth of microorganisms, reducing water loss and maintaining freshness longer.

With advanced technology, this system not only helps optimize the preservation process but also meets the strict standards of the international market, opening up sustainable export opportunities for Vietnamese agricultural products. Let’s learn more about the quick cooling system for fruits with Sancopack through the article below!

What is Rapid Cooling System for Fruit?

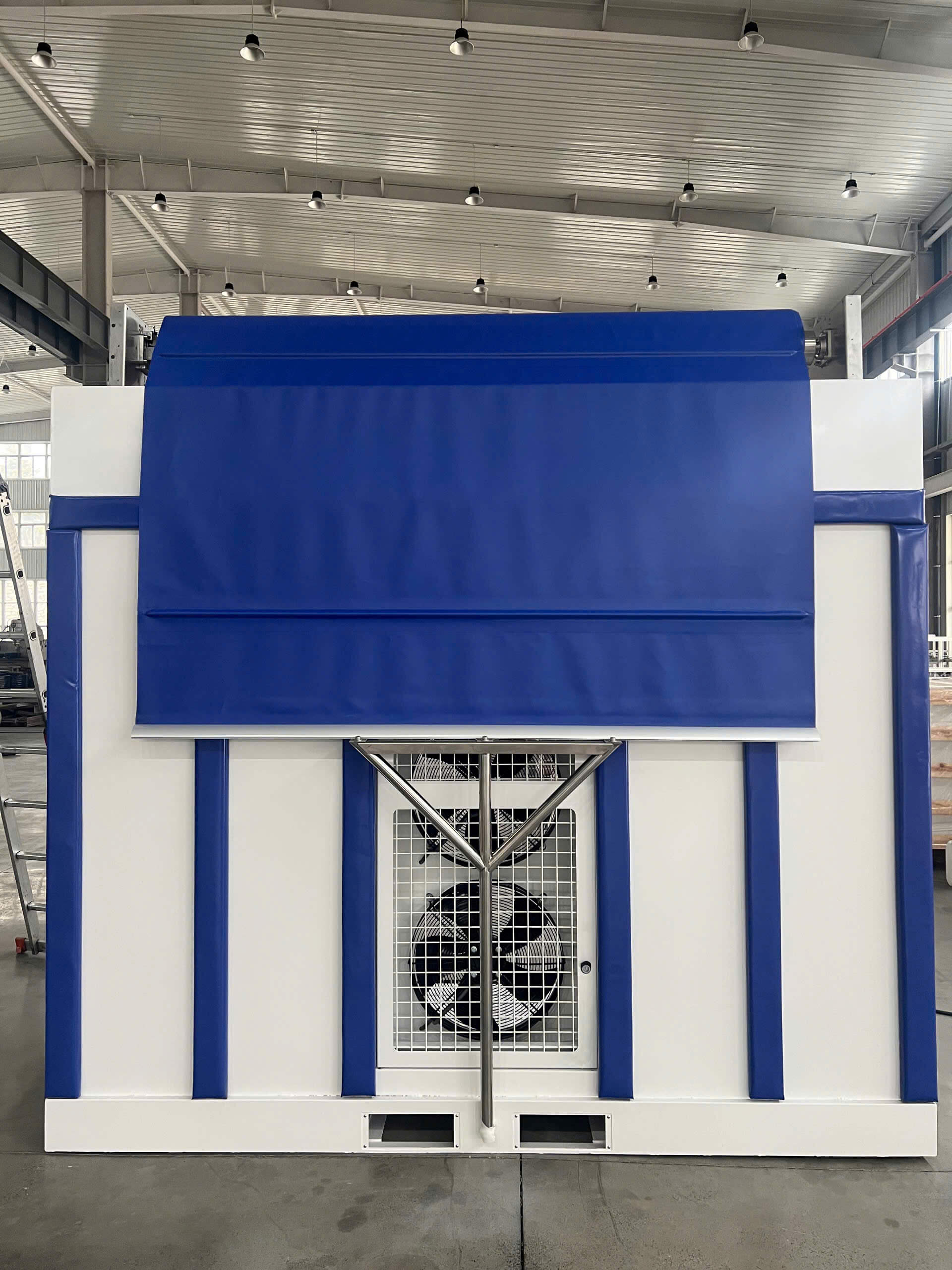

Rapid cooling system for fruits is a technology designed to reduce the temperature of fruits quickly after harvest. The main purpose of this system is to slow down the respiration process and limit the growth of bacteria and molds, helping to extend the storage time and maintain the quality of fruits.

The flash cooling system works by using powerful circulating cold air to bring the fruit temperature down to the desired level in a short time. This helps the fruit retain its freshness, natural color and flavor longer than conventional cooling methods.

>>> See More : Ways to Preserve Fresh Fruits and Vegetables for Long-Term Sale and Export

Uses of Rapid Cooling System for Fruit

The application of rapid cooling systems brings many practical benefits to agricultural enterprises and fruit supply chains. Here are some outstanding uses:

- Extended shelf life : Rapid cooling immediately after harvest slows down the ripening process and reduces enzyme activity, thereby extending shelf life. This not only reduces loss but also ensures that the fruit reaches the consumer in a fresh state.

- Preserve product quality : By minimizing the growth of bacteria and mold, the rapid cooling system helps to preserve the color, flavor and texture of the fruit. Natural nutrients and vitamins are also better preserved than traditional preservation methods.

- Reduce post-harvest losses : Post-harvest losses are one of the most pressing issues for farmers. Rapid cooling systems help reduce product loss due to spoilage, thereby increasing economic efficiency and facilitating exports.

- Optimizing transportation : When fruits are quick-frozen, they are kept in a high-quality state throughout the entire transportation process – whether by road, sea or air. This helps to reduce storage costs and increase the competitiveness of the product in the international market.

- Cost and energy savings : Although the initial investment for modern refrigeration systems may be high, in the long run, maintenance costs and product damage are significantly reduced. In addition, the application of automation technologies and smart sensors helps optimize energy usage, contributing to reduced operating costs.

Outstanding Advantages Of Rapid Cooling System

Investing in a rapid cooling system for fruit offers many advantages over traditional methods. Here are the main advantages:

Fast cooling speed

- Outstanding efficiency: The system can reduce the product temperature to the required level in a very short time, thereby preventing aging and damage.

- Versatile application: Designed to suit a wide range of fruits, from soft, vulnerable varieties to hard-skinned varieties.

Maintain quality and nutritional value

- Preserves quality: Helps retain the natural color, flavor and texture of the fruit.

- Nutrient Protection: The rapid freezing process preserves vitamins, minerals and antioxidants, keeping produce fresh and nutritious.

Minimize health risks

- Preventing the growth of microorganisms: Maintaining low temperatures helps limit the favorable environment for bacteria and mold to grow, minimizing the risk of causing disease to consumers.

- Food safety: Meet international food safety standards, contributing to enhancing the reputation of the business in the market.

Integrating modern technology

- High automation: The system is equipped with sensors and automatic control software, allowing real-time monitoring and adjustment of temperature and humidity.

- Easy to manage: Operating parameters are stored and continuously monitored, helping managers easily evaluate performance and make timely decisions.

Save operating costs

- Reduce product loss: By reducing post-harvest damage rates, businesses save costs on handling, transporting and disposing of defective products.

- High economic efficiency: Investing in a rapid cooling system not only brings quality benefits but also helps optimize resources, creating a competitive advantage in the market.

Applications Of Quick Cooling System For Fruit Provided By Sancopack

In agriculture and food processing

- Applied in fruit farms to preserve fruits immediately after harvest.

- Used in food processing plants to preserve the quality of fruit before packaging.

In the shipping and export industry

- Preserve fruit before transporting by road, sea or air.

- Ensure exported products retain their freshness and meet international quality standards.

In supermarkets and food stores

- The system helps fruits stay fresh longer, limiting damage during display.

- Increase storage time, helping to minimize losses for business units.

Sancopack Specializes in Providing Prestigious and Quality Quick Cooling Systems for Fruits in HCM, Dong Nai, Binh Duong, Hai Phong, Hanoi

The rapid cooling system for fruits is an advanced solution to extend the storage time, reduce loss and maintain product quality. With its outstanding advantages, this technology is increasingly widely applied in agriculture, food processing and export. Investing in a rapid cooling system not only helps businesses save costs but also improves product quality, meeting the increasing demands of the market.

Please contact Sancopack immediately via Hotline: 0908105115 to receive the earliest consultation and quote!