Preservation of goods

The Best Metal Protection Methods, Long-Term Corrosion Resistance

Why Is It Necessary To Protect Metal From Corrosion And Rust?

Protecting metals from corrosion and rust is very important because it affects the life and performance of metal products. This is a very common problem in the industrial, construction and manufacturing industries.

The main cause of corrosion and rusting of metals is the impact of the surrounding environment. Any environment containing chemicals such as acids, alkalis, salts or high levels of dirt and humidity can cause metals to corrode and rust.

Protecting metals from corrosion and rust can be done in a variety of ways, including the use of protective coatings, underground pipes, paints or other protective coatings. These methods can all help protect metals from the effects of the surrounding environment and prolong the life of metal products.

In addition, protecting metals from corrosion and rust also helps to increase the performance of metal products. When metals are not corroded and rusted, they will perform better and meet the requirements of users.

In summary, protecting metals from corrosion and rust is very important to prolong the life and increase the performance of metal products. There are many methods to protect metals and you should choose the method that is suitable for your environment and type of metal.

Metal protection methods are measures applied to prevent corrosion and protect metal surfaces from the effects of environmental factors. Below are some commonly used methods to protect metals:

Traditional Metal Protection Methods, Short-Term Protection

- Painting : Painting is a common method to protect metal from direct contact with the outside environment. The paint creates a protective layer on the metal surface, preventing corrosion and oxidation.

- Plating : Plating is a method of applying a coating of another metal to protect the surface of the original metal. For example, zinc plating is used to protect steel from corrosion.

- Anti-rust Film : Anti-rust film is a type of protective coating applied to metal surfaces to prevent exposure to corrosive environments and substances. Common types of anti-rust films include epoxy films, vinyl films, and polyurethane films.

- Grease : Grease is a simple method to protect metals from corrosion. Grease creates a protective layer between the metal surface and the air, preventing direct contact and the effects of environmental factors.

- Electrochemical : Electrochemical methods use the generation of electric potentials and currents to protect metals. For example, another sacrificial metal is used to protect the metal to be protected, such as the use of galvanized anodes to protect steel.

Metal Protection Methods, VCI Anti-Corrosion Technology Provides Fast & Long-Lasting Protection From 5-10 Years

1. VCI Anti-Rust Plastic Film

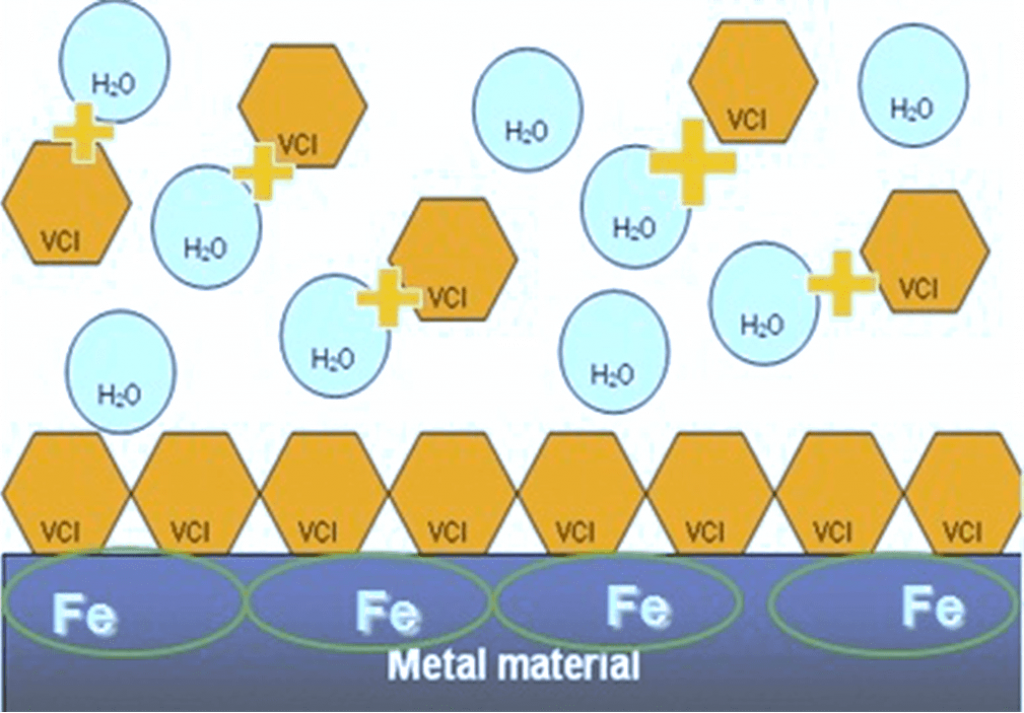

VCI anti-corrosion plastic film is a type of plastic material that contains volatile corrosion inhibitors (VCIs). These chemical compounds are used to slow or prevent the corrosion of metals, such as iron and steel.

VCIs are added as additives to packaging materials, including films and plastic bags, to protect the packaged products inside from corrosion.

VCI anti-rust plastic films work by releasing volatile corrosion inhibitors into the surrounding environment, creating a protective atmosphere around metal surfaces.

>>> See More: VCI RustX Anti-Rust Membrane

When the VCI rust-preventing resin film comes into contact with the metal, the VCIs evaporate and form a thin layer on the metal surface. This layer acts as a barrier, preventing moisture and other corrosive elements from reaching the metal and causing corrosion.

VCI anti-rust plastic film is commonly used in industries where metal components or products need to be stored or transported. It is especially useful in situations where metal products are exposed to wet or corrosive environments.

VCI anti-rust plastic film provides a convenient, economical and effective method of protection without the need for additional coatings or protective treatments.

2. VCI Anti-Rust Heat Shrink Film

Volatile Corrosion Inhibitor (VCI) shrink film is a packaging film designed to provide corrosion protection to metal products during storage and transportation.

It is made with thermal expansion technology and VCI additives, which release vapors, creating a protective layer on the metal surface, preventing corrosion and rust.

When VCI heat shrink film is heated, it shrinks tightly and wraps around the metal surface, creating a barrier against moisture, dust and other contaminants.

VCI anti-rust heat shrink film can wrap all shapes of machinery & equipment, providing a perfect protective layer.

This type of VCI anti-rust heat shrink film is commonly used in industries such as automotive, aerospace, electronics and metalworking where metal parts need to be protected from corrosion during storage or transportation.

The VCI additives in the shrink film will vaporize and release creating a protective layer of air around the metal surface.

This VCI vapor will remain continuously on the metal surface, forming a thin molecular layer that prevents the electrochemical reactions that cause corrosion. VCI technology is very effective in protecting a wide range of metals, including ferrous and non-ferrous metals.

3. VCI Anti-Rust Paper

VCI (Vapor Corrosion Inhibitor) paper is a packaging material specially designed to protect ferrous and non-ferrous metals from rust and corrosion.

It is made from Kraft paper impregnated or coated with VCI chemicals. VCI works by releasing water vapor molecules that form a protective layer on the metal surface, inhibiting the rusting process.

VCI chemicals are safe and non-toxic to humans, making VCI Anti-Rust Paper an environmentally friendly choice for metal protection.

VCI anti-rust paper is widely used in many industries, including automotive, aerospace, electronics, machinery and metal fabrication.

It is commonly used to package and wrap metal parts, components and machinery during storage, transportation and export. Paper is available in various forms such as rolls, sheets and bags, providing versatility in packaging applications.

>>> See More: SMP RustX VCI Anti-Rust Paper

Using VCI Corrosion Inhibitor Paper has many benefits. It provides long-term corrosion protection for metals, even in harsh environments. The VCI chemicals are automatically replenished, meaning protection continues even if the paper is exposed or damaged.

The paper is easy to use and does not require additional coatings or treatments. It also eliminates the need for messy and time-consuming methods such as applying oil or grease to metal surfaces.

4. VCI Anti-Rust Patch

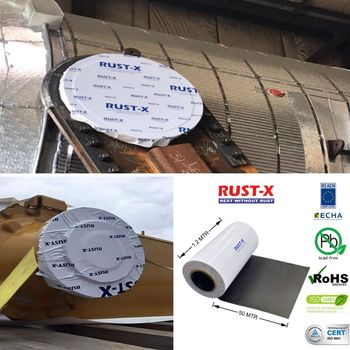

VCI RUST-X anti-rust sticker, also known as VCI Sticker, is a product used to prevent corrosion and protect surfaces in many different industries. The product is a white polymer layer integrated with VCI vaporization technology that acts as a protective coating for surfaces susceptible to corrosion.

>>> See More: VCI Rust-X Anti-Rust Patch Protects Flanges From Rust and Corrosion Effectively

The VCI (Volatile Corrosion Inhibitor) technology used in these patches helps prevent rust and corrosion on metal surfaces by releasing corrosion inhibitor vapors.

This VCI RUST-X anti-rust patch is designed for ease of use and provides a convenient solution to protect metal surfaces without the need for physical coatings or special treatments.

VCI RUST-X anti-rust patch can be applied directly to the surface and provides fast protection during storage, transportation or handling & effective protection from 2-5 years.

Contact Us for Consulting on “SANCOPACK” Anti-Rust Metal Protection Solution

If you are looking for a method to protect metal against rust , please contact “ SANCOPACK ”. With many years of experience in consulting and providing protection solutions for metal goods during storage and long-distance transportation, we will help you find the best & most suitable solution to protect your products.

We provide the best metal protection methods , including VCI anti-rust film , VCI anti-rust paper, VCI anti-rust oil,…, rust remover and other VCI anti-rust products.

>>> See More: Anti-Rust, Anti-Static – SANCOPACK

We are committed to providing high quality products, manufactured from quality components, ensuring effective protection of your metals.

In addition, with a team of highly skilled technicians, we provide technical consulting services and customer support, helping you solve problems related to metal protection and optimize your production process.

If you need advice on metal protection solutions against rust, please contact us at SANCOPACK . We will advise and help you find the best solution for your metal protection needs.

See More:

- What is Metal Rust Remover? Which Type is Good? Where to Buy?

- Top 6 Most Popular Anti-Rust Oils in the Metalworking Industry

- What Is The Best Anti-Rust Solution? Where To Buy?

- VCI Metal Corrosion Inhibitor? Where to Buy?

- Anti-Rust Spray For Motorcycles? Which Type Is Best? Where To Buy?

- What Are the Advantages and Limitations of Different Metal Corrosion Prevention Methods?

- 15 Ways to Prevent Rust That You Shouldn’t Miss

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@vietnamtravelcard.vn.vn

| ✅VCI Anti-Rust: | ⭐VCI anti-rust film, VCI anti-rust paper, anti-rust bag, anti-rust spray, VCI anti-rust oil |

| ✅Effective: | ⭐Anti-rust 5 – 10 years |

| ✅Trademark: | ⭕Rust-X (USA) |

| ✅Certification: | ⭐ ROHS, ISO 9001, ISO 14001, Confirm MIL & DIN Standards, Pass VIA |

| ✅ Phone: | ⭐ 0908105115 |