Some Causes of Cargo Rust

First we need to understand the cause of rust on metal is due to metal being exposed to high humidity environments combined with corrosive gases in the atmosphere such as: Hydrogen Chloride (HCl), Hydrogen sulphide (H2S), Nitrous Oxide (NOX), Sulphur Dioxide (SO2),…

Why Should You Protect Your Goods From Rust Immediately?

We should find an effective way to prevent rust immediately for goods whether they are unused or in use. Because once the goods are rusted, their quality will decrease significantly.

Rust-X 2D VCI anti-corrosion and anti-rust plastic bag

Unused goods will no longer be usable or will incur repair costs.

If the goods are in use, rust will affect other production processes. Therefore, if we do not find a way to preserve the goods immediately, it will cause great losses to the users.

How to prevent iron from rusting? We can prevent this process from happening by the following anti-rust methods :

1. Galvanizing

Galvanizing is one of the most effective methods of preventing rust on metal products. In this process, a layer of zinc is applied to the metal surface.

Zinc is a highly reactive metal and acts as a sacrificial anode and rusts instead of iron or steel.

This prevents the metal from rusting. Galvanizing is commonly used for products such as pipes, roofs and fences.

2. Powder Coating

Powder coating is a popular way to prevent rust on metal products. In this process, a dry powder is sprayed onto the metal surface and then baked at high temperatures.

The heat causes the powder to melt and form a protective layer on the metal surface. Powder coating is commonly used for outdoor furniture, cars and bicycles.

3. VCI Anti-Rust Oil

VCI Anti-Rust Lubricant , also known as Volatile Corrosion Inhibitor, is a chemical used to protect metal surfaces from corrosion and oxidation.

It works by releasing volatile molecules that form a protective layer on the metal, inhibiting corrosion. VCI is commonly used in many industries, including automotive, manufacturing, and packaging.

VCI rust inhibitor is a simple and cost-effective method to prevent rust on metal products. In this method, a layer of oil is applied to the metal surface.

This VCI rust preventive lubricant acts as a barrier between the metal and the environment, preventing moisture and oxygen from reaching the metal surface. VCI rust preventive solutions are commonly used for small metal products such as tools and machinery.

4. Electroplating

Electroplating is a process in which a metallic coating is applied to the surface of a metal product by passing an electric current through a solution containing the coating metal.

This anti-rust method not only prevents rust but also improves the aesthetics of the product. Electroplating is often used for jewelry, tableware and decorative products.

5. Anti-Rust Paint

Anti-rust paint is a popular method to prevent rusting of metal products exposed to moisture and sunlight.

Anti-rust paint creates a protective layer on the metal surface, preventing moisture and oxygen from reaching the metal surface. Paint is often used on products such as outdoor furniture, gates and fences.

7. Lubrication

Lubrication is an effective method of preventing rust on moving metal parts such as hinges and locks.

Using a thin layer of lubricant on metal surfaces can help reduce friction and prevent rust from forming. Lubricants are commonly used for automotive and industrial applications.

8. Use Metal Rust Preventative

Metal rust inhibitors are chemical compounds added to metal products to prevent the formation of rust.

These compounds work by creating a protective layer on the metal surface, preventing moisture and oxygen from reaching the metal surface. Metal rust inhibitors are commonly used on metal products such as pipes, machinery and tools.

9. Use Stainless Steel

Stainless steel is a type of steel that contains Chromium, making it highly resistant to rust .

Rust is a common problem that affects metal products. It not only reduces the aesthetic appeal of the product but also weakens the structure, leading to reduced durability and functionality.

Therefore, implementing rust prevention methods is very important to ensure your metal products are kept in optimal condition for a long time.

10. Keep Surfaces Clean

Keeping the surface of metal products clean can also help prevent rust from forming. Dirt and debris can trap moisture on metal surfaces, creating ideal conditions for rust to form.

Regular cleaning of metal products can help remove dirt and debris and keep the surface dry.

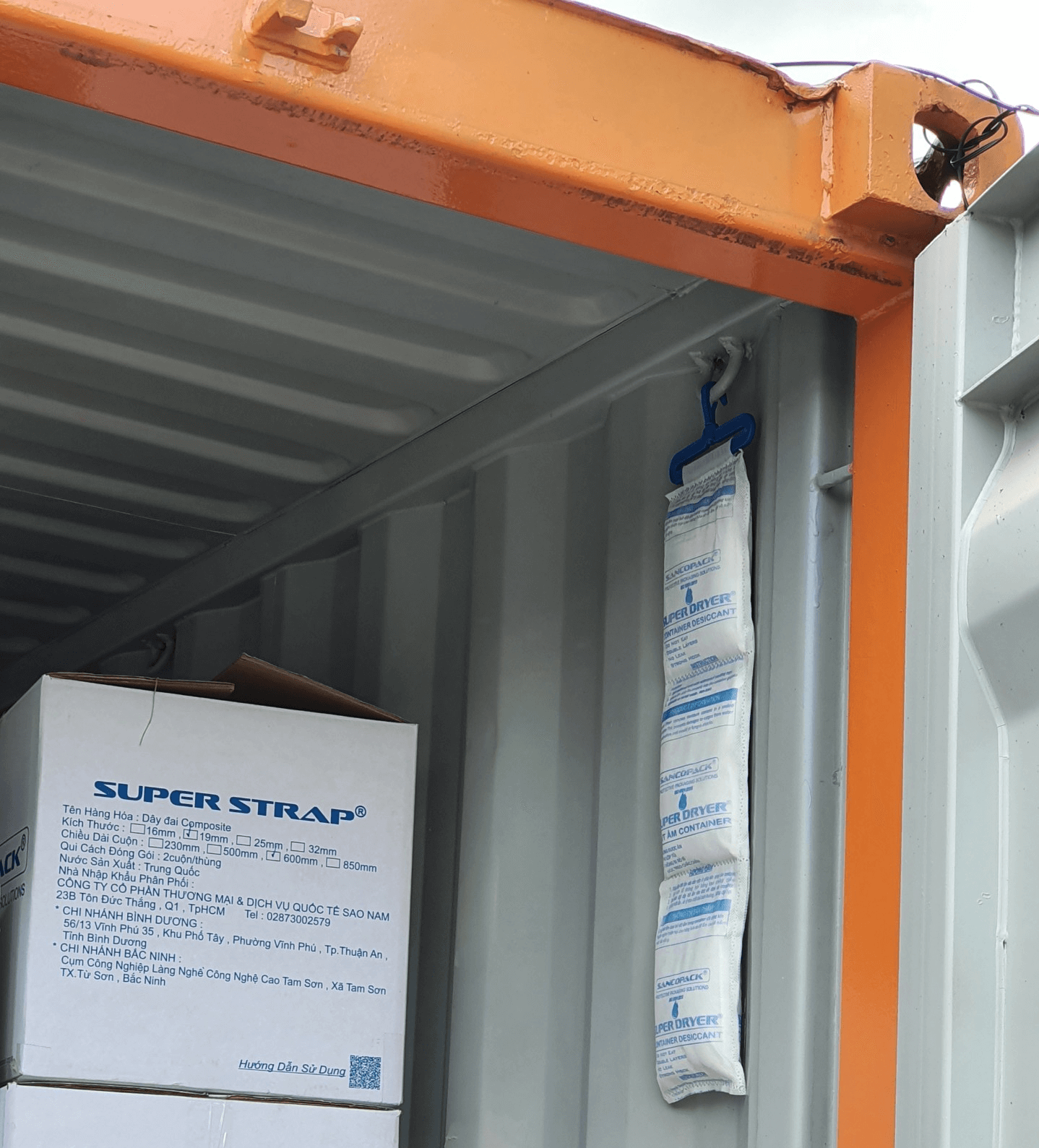

11. Rust-Proof Desiccant Bag

Anti-rust desiccant bags are indispensable products in preserving metal products. Especially products that are easily affected by environmental conditions such as humidity, temperature and air impact.

Anti-rust desiccant bags are made from specialized super absorbent particles, capable of absorbing moisture from 50% to 300% of the weight of the desiccant bag itself (the ability to absorb moisture depends on the inner wall of the bag).

With high moisture absorption capacity, anti-rust desiccant bags help metal products avoid the effects of humidity and air, thereby helping to keep the product in the best condition.

Anti-rust desiccant bags come in many different sizes and types to suit each specific product. To ensure effective use, consumers need to pay attention to the number of desiccant bags needed for each product as well as the time to replace the desiccant bags to ensure the best preservation for metal products.

With its outstanding advantages, anti-rust desiccant bags are becoming increasingly popular in preserving metal products and are widely used in many fields such as manufacturing, transporting and preserving metal products.

12. VCI Anti-Rust Film Packaging

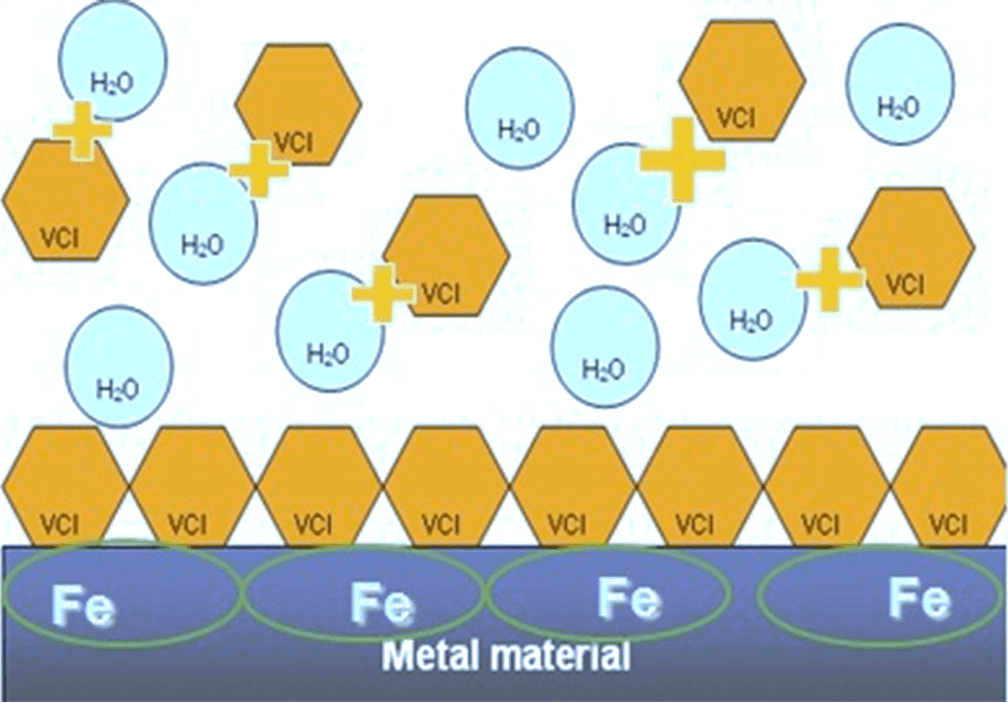

VCI anti-rust film packaging is a popular packaging solution designed to effectively protect metals and metal parts from rust and corrosion. It is a simple and effective packaging option that is easy to use, easy to clean and dry.

VCI, short for vapor corrosion inhibitor, is a type of chemical compound infused into various packaging materials, including poly sheets, paper, emitters, chipboard, desiccants and other components.

When metal parts are properly protected with anti-rust VCI packaging products, which contain activated VCI ions.

VCI ions create a protective shield on the metal surface, repelling moisture and removing rust.

Using VCI rust-preventing film, you can safely prevent corrosion of protected metals without the need for grease, protective paint or any other time-consuming protection methods.

In summary, VCI anti-rust film packaging is a reliable and effective way to protect metals and metal parts from rust and corrosion. It is easy to use, easy to clean and dry.

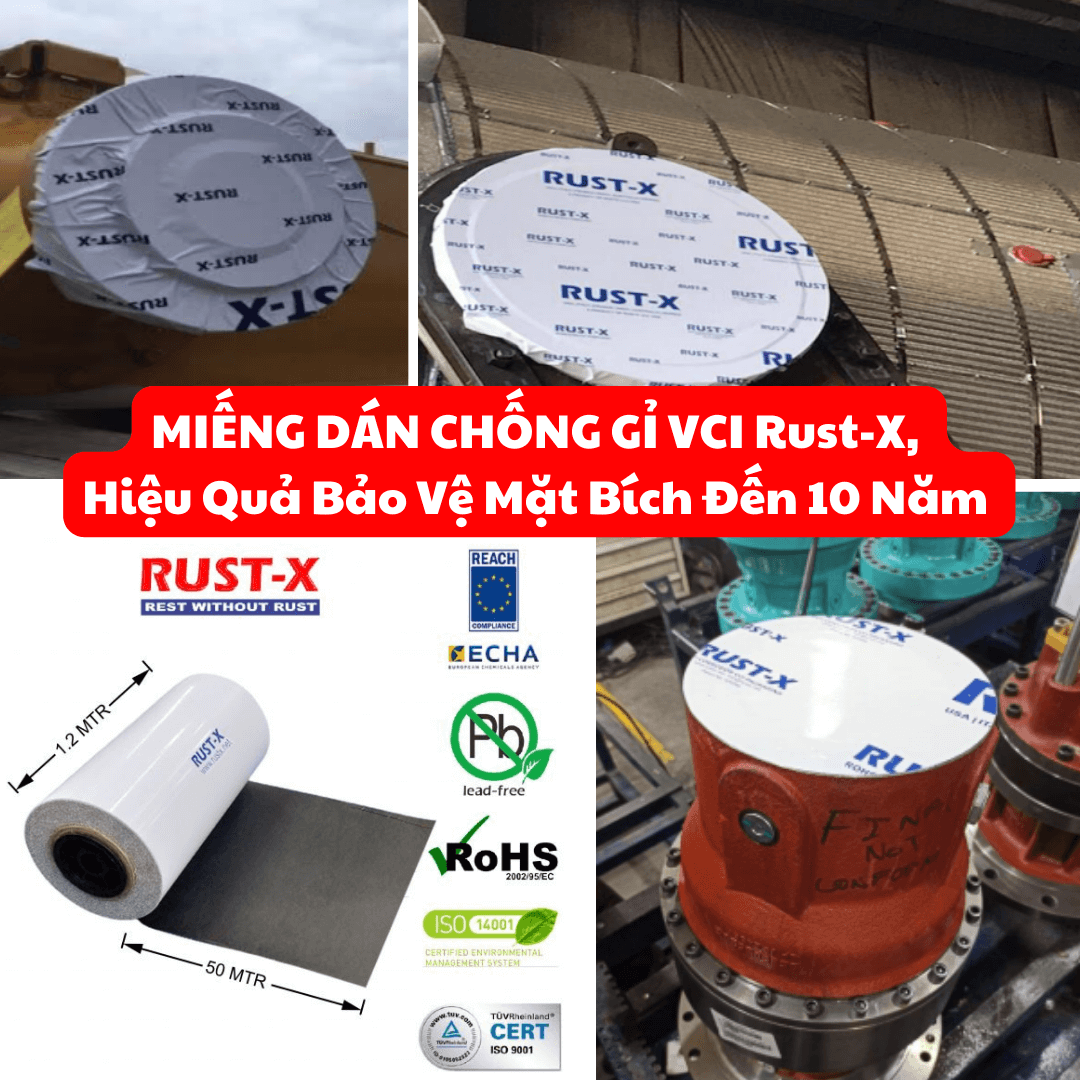

15. VCI Rust-X Anti-Rust Paper

VCI (Volatile Corrosion Inhibitor) anti-rust paper is a type of paper impregnated with VCI solution, used to protect machinery, equipment and metal products from corrosion and oxidation.

VCI anti-rust paper has the ability to create a protective film on the metal surface, preventing contact between the metal and the air, helping to protect the product from corrosion. This helps to prolong the life and durability of machinery, equipment and metal products.

Benefits of using VCI anti-rust paper include:

1. Prevents corrosion: VCI anti-rust paper creates a protective environment of moisture and air, preventing oxidation and corrosion of metals. This helps to minimize damage caused by rust and prolong the life of machinery, equipment and metal products.

2. Comprehensive protection: VCI rust-proof paper is capable of protecting the entire metal surface, including crevices and hard-to-reach parts. The use of VCI rust-proof paper ensures a uniform protective film on the entire metal surface, while eliminating the need for other maintenance agents such as grease.

3. Save on maintenance costs: By preventing corrosion and oxidation, VCI anti-rust paper helps reduce maintenance costs and replace damaged parts. This means saving time and resources in maintaining and repairing machinery and equipment.

4. Easy to use and maintain: VCI anti-rust paper can be easily cut, folded and shaped to suit different sizes and shapes of machinery, equipment and metal products.

In addition, one of the biggest benefits of using VCI anti-rust paper is its comprehensive protection ability. This paper can create a protective film on the metal surface, preventing contact between the metal and the air. This helps protect the product from corrosion and oxidation, prolonging the life and durability of machinery, equipment and metal products.

>>> See Details: SMP RustX VCI Anti-Rust Paper

The use of VCI paper also provides the benefit of saving on maintenance costs. By preventing corrosion and oxidation, VCI paper helps to reduce maintenance costs and the replacement of damaged parts. This saves time and resources in the maintenance and repair of machinery and equipment.

In addition, the use of VCI anti-rust paper can also replace the use of traditional grease. This saves manpower and time, while minimizing the risk of environmental pollution.

13. Intercept Advanced Anti-Rust Technology

Using Intercept’s advanced anti-rust technology: If you need an anti-rust method that is oil-free and chemical-free, easy to apply, reusable and lasts for more than 2 years, Intercept’s anti-rust solutions are the perfect choice.

Currently, this technology is available in the form of membrane , bag , foam, or anti-rust canvas, which is very convenient for us to choose from.

Not only does Intercept technology prevent rust on metal, it also applies anti-corrosion to other materials such as rubber, plastic…

14. Perform Regular Checks

Regular inspection of metal products can help detect rust formation early and prevent further damage.

Inspect metal products for signs of rust, including discoloration, peeling, and chipping. If you see any signs of rust, take immediate action to prevent further damage.

Sancopack Provides High Quality Anti-Rust, Anti-Corrosion Using The Most Modern VCI SMP Technology

What is VCI SMP Anti-Rust Technology?

- VCI: Volatile Corrosion Inhibitor – Volatile rust inhibitor.

- SMP: Speedy Moisture Passivation – Instantly neutralizes moisture.

VCI SMP technology helps prevent rust and corrosion on metal surfaces of equipment quickly and maintains it for a long time.

>>> See More: What Are The Advantages And Limitations Of Different Metal Anti-Corrosion Methods?

When using VCI SMP technology on machinery, equipment, components, etc., VCI will evaporate to form a protective layer on the metal surface to prevent rust and corrosion.

20% of the VCI active ingredient will be released from the first second and continuously for 6 hours, the remaining 80% of the VCI will be released gradually over 5 to 15 years.

Below are products created using VCI SMP technology , customized in many different forms such as: bags, films, lining films, solutions, aluminum films, VCI paper films,… suitable for all goods that need to be preserved, protected from rust and corrosion during long-term storage or transportation.

Advantages of VCI SMP Anti-Rust Technology

- Creates a moisture-proof film on metal surfaces.

- Prevents moisture from condensing into water droplets.

- Inactivates electrolytic oxidation reactions.

- Control pH to neutral level.

The Best Ways to Prevent Rust with VCI

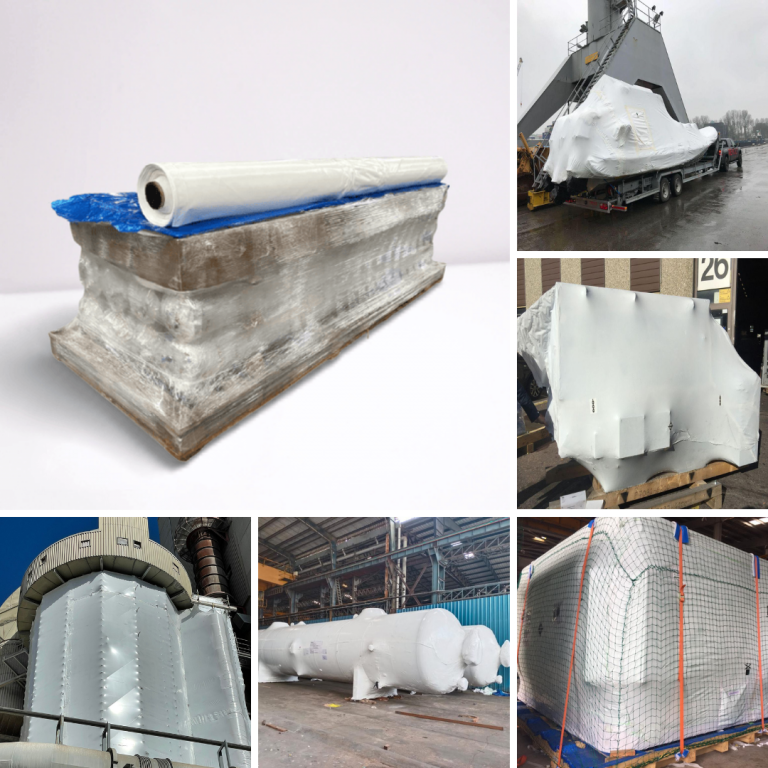

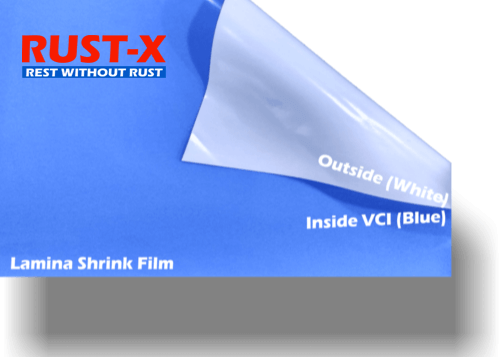

1. Lamina Rust-X VCI Heat Shrink Film

VCI Lamina Rust-X heat shrink film is produced using modern VCI SMP technology , has the ability to absorb moisture quickly and provide long-term corrosion protection for packaged components, machinery and equipment.

Suitable for ferrous and non-ferrous metals, and inhibits the development of corrosion, tarnish, etc. for up to 5 years.

Features of Lamina Rust-X VCI Heat Shrink Film

- Products with many outstanding features such as: abrasion resistance, movement restriction, water and moisture resistance,…

- Strong and highly flexible, suitable for all types of machinery, equipment,…

- VCI multi-metal protection for all surfaces.

- Extremely high elasticity.

- High tear resistance due to multi-molecular bonding for increased strength.

- Quick to use, easy to remove and recycle.

>>> See Details: VCI Heat Shrink Film Lamina Rust-X

2. Rust-X 3D VCI Pallet Liner

Sealing the package is very important to ensure that moisture from the outside does not penetrate inside and cause damage, corrosion, or rust to the goods inside.

Rust-X 3D VCI plastic film wraps pallets tightly, completely preventing the penetration of seawater vapor during shipping.

>>> See Details: Rust-X 3D VCI Pallet Lining Film

Specifications

- Thickness: 75 to 300 microns

- Roll length: 5 to 500 cm

- Color: blue / yellow / transparent.

- Printing: up to 8 colors.

- Suitable for pallet types: 704 G, 704 XH 704 FL,…

3. Rust-X 3D VCI Anti-Rust Film for Carton Lining to Prevent Moisture and Rust

Corrugated cardboard boxes contain a lot of moisture. Rust-X 3D VCI plastic film is used to protect steel components from moisture (risk of rust, corrosion).

Specifications

- Thickness: 75 to 300 microns.

- Roll width: 25 to 500 cm / roll.

- Color: Blue / Yellow / Transparent.

- Printing: up to 8 colors.

- Plastic film suitable for carton sizes: code 703G, 703 XH, 703 FL,…

>>> See Details: VCI RustX Anti-Rust Film for Covering and Preventing Rust on Machinery and Equipment Components

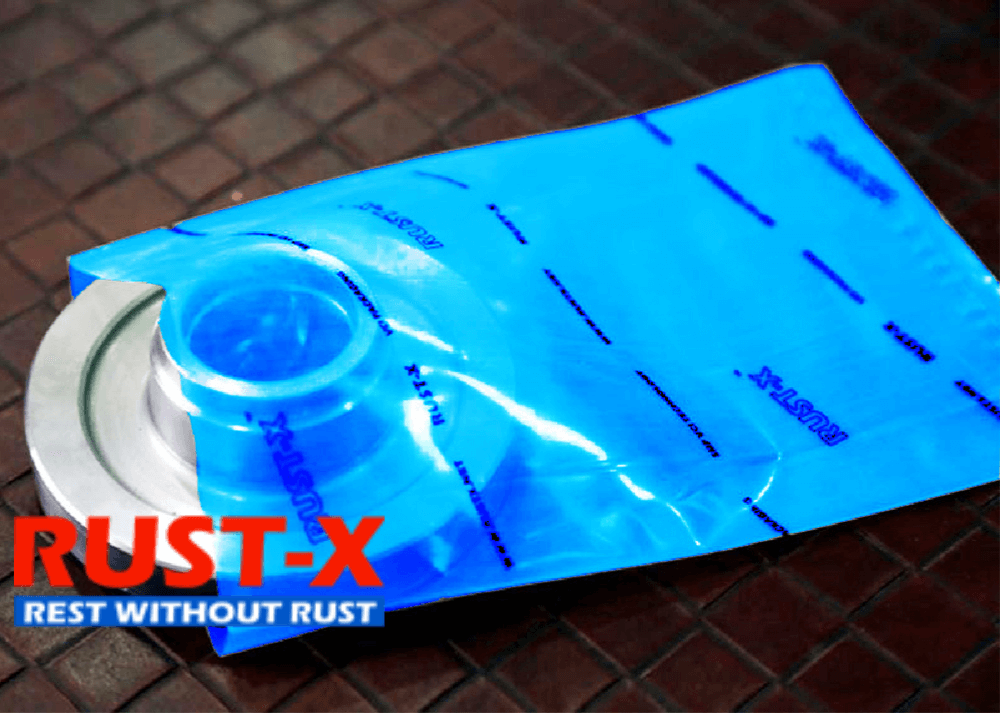

4. Rust-X 2D VCI Anti-Rust Bag Provides Fast, Long-Lasting Protection

VCI 2D Rust-X anti-rust bag is specialized in preserving machine and electronic components,… to avoid rust and corrosion. Suitable for long-term storage and transportation.

The product adopts SMP technology and integrates VCI (Volatile Corrosion Inhibitor) active ingredient to prevent/corrosion/wear.

Specifications

- Bag thickness: 75 to 500 microns

- Bag size: width: 5 to 500 cm

- Length: optional

- Color: Blue / Yellow / Transparent

- Printing: up to 8 colors

>>> See Details: Rust-X 2D VCI Anti-Corrosion and Anti-Rust Bag

5. VCI Rust-Proof Membrane – X

VCI Rust-X anti-rust film in sheet/roll form comes in many sizes, used to cover components, machinery, equipment,… and creates a protective layer on the surface, helping to prevent corrosion and rust.

Specifications

- Thickness: 50 to 500 microns

- Roll length: 5 to 500 cm

- Panel size: optional

- Color: Blue / yellow / transparent

- Printing: up to 8 colors

>>> See More: VCI Anti-Rust Film Sheet/Roll Rust – X

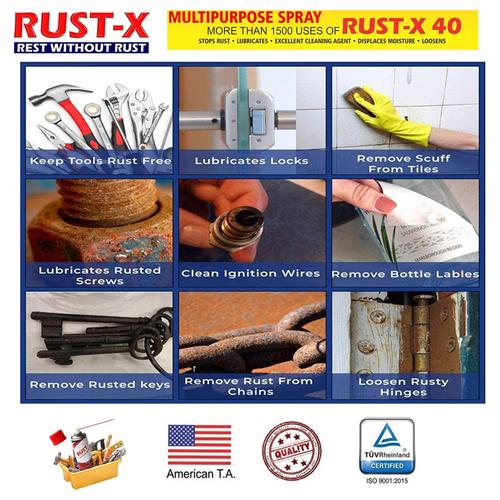

6. Rust X 40 Multi-Purpose Anti-Rust Spray

RUST-X 40 Multi-Purpose Rust Preventative Spray is an excellent degreaser and rust preventative for removing heavy and light waxy coatings from metal surfaces.

Works well on steel, aluminum, iron, brass, copper, zinc, nickel, chromium and other multi-metal systems. Provides 2 – 3 years of rust protection under normal packaging, storage,…

Main Features of RUST-X 40 Multi-Purpose Anti-Rust Spray

- High performance coating remover.

- Good for light oils and greases.

- Will not affect painted surfaces.

- Mainly used at room temperature.

- Works well on steel, aluminum, iron, brass, copper, zinc, nickel, chrome and other multi-metal systems.

- Forms a durable, moisture-resistant, corrosion-resistant protective coating.

- Provides a good insulation layer on applied surfaces.

- Provides long lasting protection.

- No ozone depleting substances.

>> See Details: Rust X 40 Multi-Purpose Anti-Rust Spray

7. VCI Anti-Rust Paper – Rust-X

- Convenient for packaging machinery, components, and equipment because VCI anti-rust paper is quick to use, easy to clean, and does not pollute the environment.

- Preservative effect for metal surfaces for quick and long-lasting protection from 3 to 5 years.

- The cost of using VCI anti-rust paper is cheaper than other anti-rust solutions.

- Surface protection for multi-metals: ferrous metals, aluminum alloys, non-ferrous metals, copper, steel, iron, etc.

- Various sizes, easy to cover all metal products with special shapes.

>>> See Details: What is VCI Anti-Rust Paper? How Long Can It Be Used? Where to Buy?

Introducing Rust – X – The Leading Anti-Rust Brand From America, India

RUST-X is the market leader in rust and corrosion protection, with over 600 product lines manufactured in factories around the world. Rust-X currently has over 10,000 customers globally across most industries.

>>> See Details: Top Ways to Prevent Rust and Metal Corrosion Rust – X

With a large team of rust and corrosion experts, with more than 250 members worldwide. RUST-X has more than 600 products in the field of packaging, rust and corrosion protection.

Continuous research and development (R&D) based on diverse customer needs by our field and laboratory engineers has helped develop this product line.

Currently, RUST-X has factories spread across the globe such as the US, France, Italy and India. With more than 600 ROHS compliant products with diverse types and designs.

Summary

In conclusion, rust prevention is important to maintain the functionality and aesthetics of metal products.

There are several ways to prevent rust including: galvanizing, powder coating, oil coating, electroplating, painting, avoiding exposure to moisture, lubricating, using rust inhibitors, using stainless steel, keeping the surface clean, using dehumidifiers, VCI rust inhibitors, performing regular inspections and proper storage.

By applying these rust prevention methods , you can extend the life of your metal products and avoid expensive repair or replacement costs.

See More:

- What is Metal Rust Remover? Which Type is Good? Where to Buy?

- Top 6 Most Popular Anti-Rust Oils in the Metalworking Industry

- What Is The Best Anti-Rust Solution? Where To Buy?

- VCI Metal Corrosion Inhibitor? Where to Buy?

- Anti-Rust Spray For Motorcycles? Which Type Is Best? Where To Buy?

- What Are the Advantages and Limitations of Different Metal Corrosion Prevention Methods?

- VCI Anti-Rust Agent

- VCI RustX Anti-Rust Membrane

- Rust-X 40 Multi-Purpose Anti-Rust Spray

- Rust-X 2D VCI Anti-Rust Bag

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@vietnamtravelcard.vn.vn

| ✅VCI Anti-Rust: | ⭐Anti-rust plastic film, anti-rust paper, anti-rust bag, anti-rust spray, VCI anti-rust oil |

| ✅Effective: | ⭐Anti-rust 5 – 10 years |

| ✅Trademark: | ⭕Rust-X (USA) |

| ✅Certification: | ⭐ ROHS, ISO 9001, ISO 14001, Confirm MIL & DIN Standards, Pass VIA |

| ✅ Phone: | ⭐ 0908105115 |