Anti-Rust VCI Shrink Film Rust-X

Anti-rust VCI shrink film Rust-X has many sizes, used to cover components, machinery, equipment, etc. and create a protective layer on the surface, helping to prevent corrosion and rust.

What Is Rust Corrosion?

Corrosion is a chemical reaction that causes destruction of metal surfaces due to oxidation or reactions between chemicals. Corrosion control has become an important area in the machinery manufacturing industry.

There are many solutions to prevent corrosion and rust, but VCI technology is the most advanced, effective, cost-effective, environmentally and user-friendly solution.

What Is Anti-Rust VCI Shrink Film Rust-X?

VCI (Volatile Corrosion Inhibitor) anti-rust shrink film is a type of anti-rust film used for packaging to protect large machinery and equipment from corrosion and rust.

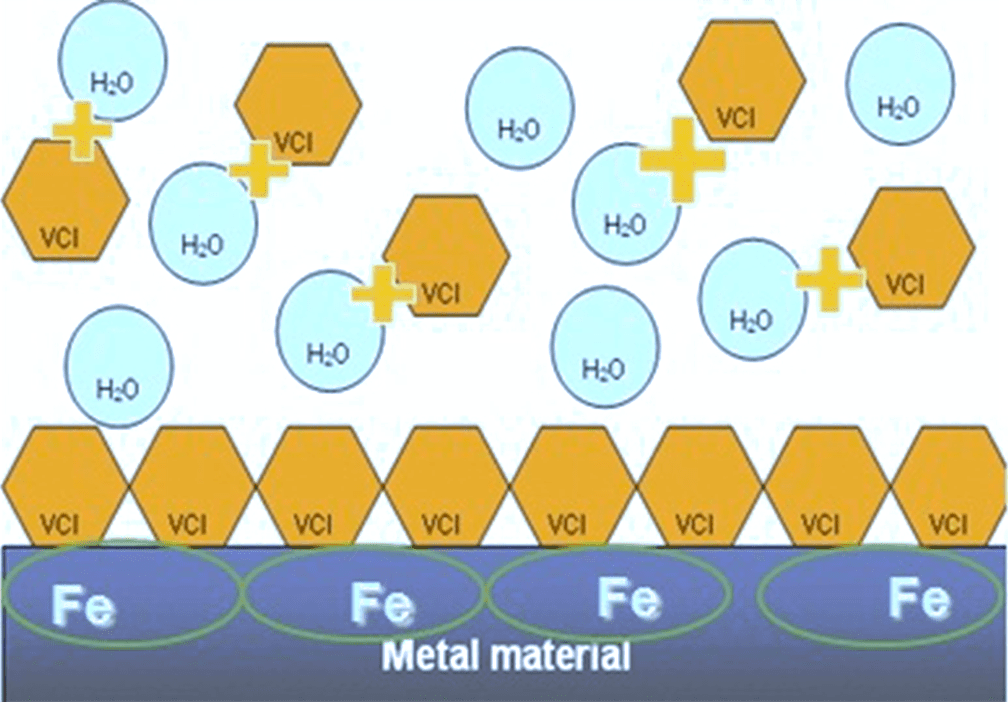

This film contains VCI anti-corrosion agents. When exposed to air, it creates an anti-oxidant layer on the metal surface to prevent rust from occurring.

Anti-rust VCI shrink film Rust-X is often used during packaging, transportation and storage of machinery and equipment, helping to protect them from the impact of the surrounding environment.

There are many types of anti-rust VCI shrink film used for large machinery and equipment, including VCI anti-rust PE and VCI rust film.

VCI anti-rust PE film is usually made from polyethylene resin and is capable of creating an antioxidant film on the metal surface. VCI anti -rust film also has the same function, but is usually made from nylon or polyethylene.

Using anti-rust VCI shrink film Rust-X for large machinery and equipment prolongs their life, minimizes corrosion and rust, and keeps them operating efficiently over the long term. This is an effective and economical storage solution for industries that use large machinery and equipment such as manufacturing, construction, and energy.

Introducing Anti-Rust VCI Shrink Film Rust-X

Anti-rust VCI shrink film is manufactured using VCI SMP technology, which is a technology that prevents rust and corrosion on metal surfaces of equipment quickly and maintains it for a long time.

How To Use Anti-Rust VCI Shrink Film Rust-X?

When using anti-rust VCI shrink film Rust-X to cover and preserve machinery, equipment, etc., the VCI substance inside the plastic film will evaporate to form a protective layer on the metal surface from rust and corrosion.

20% of VCI active ingredients will spread from the first second and continuously during the first 6 hours of use, the remaining 80% of VCI will gradually spread over 5 to 15 years.

Advantages Of Anti-Rust VCI Shrink Film Rust-X

- Creates a moisture-proof film on metal surfaces.

- Prevents moisture from condensing into water droplets.

- Disable electrolytic oxidation reactions.

- Control pH at neutral level.

Anti-Rust VCI Shrink Film RustX Technical Specifications

- Thickness: 50 to 500 microns

- Roll length: 5 to 500 cm

- Sheet size: optional

- Color: Green/yellow/transparent

- Printing: up to 8 colors

How To Use Anti-Rust VCI Shrink Film Rust-X For Large Machinery And Equipment

How to use anti-rust VCI shrink film Rust-X for large machinery and equipment as follows:

- Clean and dry the surface of machinery and equipment before using VCI anti-rust membrane.

- Wrap VCI RUSTX anti-rust film tightly around machinery and equipment to form a protective layer.

- Make sure there are no gaps or openings in the VCI metal anti-corrosion film coating.

- If machinery or equipment has individual components, wrap each component with VCI anti-rust film before reassembling.

- When storing machinery and equipment, make sure the storage environment is dry enough and free of aggressive substances that can break the protective layer of the VCI RUSTX anti-corrosion membrane.

- Monitor usage time and periodically check the protective layer of VCI anti-rust membrane. If necessary, replace or add a new film to ensure effective protection.

- When you need to reuse machinery and equipment, remove the VCI anti-rust film cover and clean the surface before use.

Note: Please follow the specific instructions from the VCI anti-rust film manufacturer and apply the appropriate usage method for each specific type of machinery and equipment.

Advantages Of Anti-Rust VCI Shrink Film RustX

Anti-rust VCI shrink film is a packaging material used in preserving large machinery and equipment to prevent rust and metal wear.

Below are some advantages of VCI anti-rust membrane:

- Anti-rust effect: VCI anti-rust film is highly effective in preserving machinery and equipment. It helps prevent corrosion and rust by creating a protective layer on metal surfaces. When used, the VCI in plastic film will evaporate and form a protective layer, protecting machinery and equipment from the effects of the surrounding environment. This helps prolong their lifespan and ensures efficient operation over a long period of time. However, to achieve the best results, follow specific instructions from the VCI anti-rust film manufacturer and apply the appropriate usage method for each specific type of machinery and equipment.

- Ease of use: VCI anti-rust film can be easily applied to metal surfaces without the need to use other preservatives such as oil or grease. It is also easy to remove and reuse when needed.

- Comprehensive protection: VCI anti-rust film has the ability to penetrate small gaps and crevices on metal surfaces, providing comprehensive protection and preventing the impact of rust from the inside.

About Rust – X?

RUST-X is the market leading brand in the field of rust and corrosion protection, with more than 600 product lines produced at factories around the world. Rust-X currently has more than 10,000 customers globally in almost every industry.

With a large team of rust and anti-corrosion experts, with more than 250 members around the world. RUST-X has more than 600 products in the field of packaging, anti-corrosion and rust prevention.

Continuous research and development (R&D) by a team of field and laboratory engineers based on diverse customer needs has helped develop this product series.

Currently, RUST-X has factories spread across the globe such as the US, France, Italy and India. With more than 600 products meeting ROHS standards, diverse in types and designs.

Certification Of Quality And Safety Of Anti-Rust VCI Rust-X Products

- ROHS Compliant (Restriction of Hazardous Substances Directive): Directive on restricting hazardous substances.

- Confirm MIL & DIN standards: confirm durability standards.

- Pass VIA (Vapor-Inhibiting Ability) recommended test: Passes the vapor inhibition ability test.

RUST-X Contact Information

RUST–X Is Exclusively Distributed In Vietnam By SAO NAM INTERNATIONAL TRADING & SERVICES JOINT STOCK COMPANY (SANCOPACK).

- Address: 8 Hoang Minh Giam, Phu Nhuan District, Ho Chi Minh, Vietnam

- Email: info@sancoemail.com

- Hotline: 0987.905.554

- Phone: 0989930650 (Southern Sales)

- Phone: 0979780737 (Northern Sales)

HOTLINE: 028.73002579 (HCM) – 024.73002579 (Hà Nội)

Nhận tư vấn và đặt mua sản phẩm uy tín chất lượng tại:

CÔNG TY CP SAO NAM (SANCOPACK)

Email: info@vietnamtravelcard.vn.vn

| ✅ Chống gỉ sét VCI: | ⭐ Màng chống gỉ VCI, giấy chống gỉ VCI, túi chống gỉ, chai xịt chống gỉ sét, dầu chống rỉ sét VCI |

| ✅ Hiệu quả: | ⭐ Chống gỉ sét 5 – 10 năm |

| ✅ Thương hiệu: | ⭕ Rust-X (Mỹ) |

| ✅ Chứng nhận: | ⭐ ROHS, ISO 9001, ISO 14001, Confirm MIL & DIN Standards, Pass VIA |

| ✅ Phone: | ⭐ 0987.905.554 |