Preservation of goods

Container Packing & Lashing Service With Good Price

SANCOPACK is a professional container packing service provider, ensuring competitive prices, safety and speed.

SANCOPACK ‘s container packing service is designed to meet the needs of businesses transporting goods from Vietnam to countries around the world.

SANCOPACK provides professional packaging services and protects goods from external impacts during transportation.

With a team of experienced and professional staff, SANCOPACK ensures that all container packing processes are carried out in the safest and most accurate manner.

>>> See More: Dunnage Air Bag Container Good Price

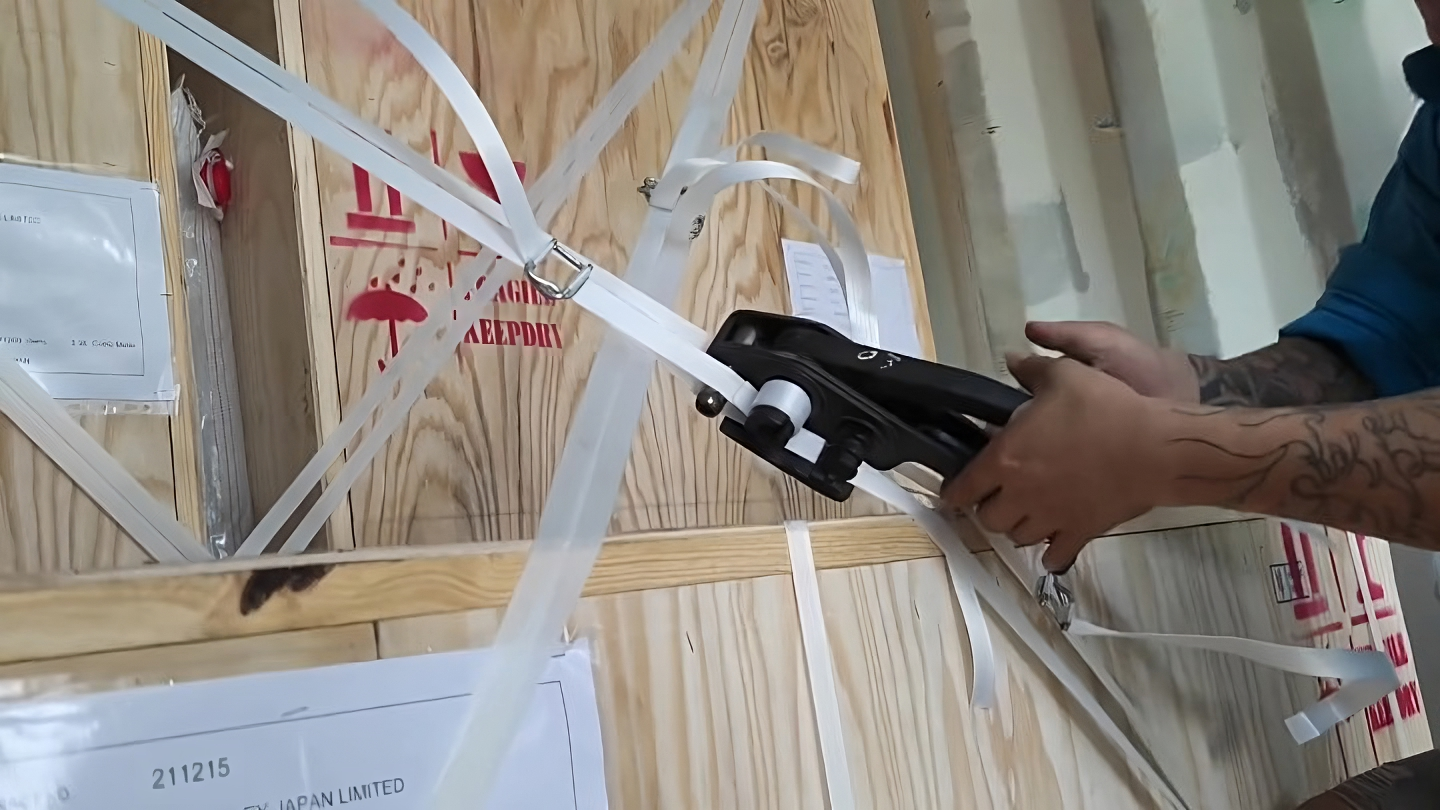

In addition, SANCOPACK also uses advanced equipment, tools, materials and technology to pack goods to ensure the quality and efficiency of shipping goods to customers.

SANCOPACK offers competitive prices for container lashing services , while ensuring the quality and safety of goods. Customers can rest assured about SANCOPACK ‘s prices and services .

>>> See More : Export Goods Packaging Service in Binh, Dong Nai, Hanoi, Bac Ninh, Ho Chi Minh City – Sancopack

Container Loading Process

Containerization is one of the important services of the shipping industry. It is used to transport goods from one location to another by sea.

The process of packing goods into containers includes the following steps:

- Container preparation : Before loading goods into a container, it is necessary to inspect the container to ensure it meets safety and capacity standards.

- Containerization : After the container inspection, the goods will be loaded into the container. This needs to be done carefully to avoid damage or loss of goods during transportation.

- Container sealing : After packing the goods into the container, it is necessary to seal the container to ensure that the goods do not fall or spill during transportation.

- Container Shipping : Finally, the container will be transported to the destination. This needs to be done safely and ensure that the goods are not damaged or lost during transportation.

Container packing service brings many benefits to businesses and individuals when transporting goods. It helps save transportation costs, ensures the safety of goods and minimizes risks during transportation.

Container Loading Technique

Packing goods into containers is an important task in the process of transporting goods. Proper packaging and arrangement of goods will help ensure the safety of goods and minimize risks during transportation.

To properly pack goods into containers, the following principles must be followed:

- First, it is necessary to check the volume and size of the goods to choose the appropriate type of container.

- Then, it is necessary to pack the goods with sturdy materials such as: carton packaging, tape, container air bags, composite straps , polyester fabric straps , wooden crates, wooden pallets…, iron bars, strap tensioning equipment.

- Next, it is necessary to arrange the goods in the container tightly, evenly and without leaving any gaps. You can use bollards or airbags to keep the goods stable and not collide during transportation.

- Finally, the container lid should be closed and checked carefully before shipping.

>>> See More: Durable SPLASH Polyester Fabric Straps , Withstand 10 Tons of Goods – Lashing Straps

Proper lashing of goods into containers will help protect the goods and ensure safety during transportation. This also helps increase efficiency and save costs during transportation.

How to Calculate Container Loading

Container loading is an important task in the process of transporting goods. To ensure the safety of goods, we need to calculate to maximize the area and volume of the container. Here are some basic steps to calculate lashing goods into containers .

Step 1: Determine Container Size

Before packing, we need to know the size of the container we will use. Common container sizes include 20 feet, 40 feet, and 40 feet high cube. Once we know the dimensions of the container, we can calculate its area and volume.

Step 2: Determine the Size of the Goods

After knowing the container size, we need to determine the size of the goods. This helps us calculate the most optimal quantity and packing style.

Step 3: Calculate the Quantity of Goods Needed to be Packed in the Container

Based on the size of the goods and the container, we can calculate the quantity of goods that need to be packed into the container. This helps us ensure maximum use of the container space.

Step 4: Determine How to Pack Goods into Container

There are many ways to tie down cargo into a container , but it is important to ensure the safety of the cargo. Some common ways of packing cargo include vertical packing, horizontal packing, or a combination of both. We need to determine the most optimal way of packing cargo to save space and ensure the safety of the cargo.

Calculating lashing of cargo into containers is an important process to ensure cargo safety and optimize container space and volume.

With the basic steps above, we can calculate the packing of goods into containers effectively and accurately.

Introduction: Container Lashing Certificate Service – SANCOPACK

SANCOPACK is one of the leading companies providing container lashing certificate services in Vietnam. This service provides solutions for connecting container lashing systems according to international standards to ensure the safety of goods during transportation.

SANCOPACK has been certified as a reliable container lashing certificate service provider by professional organizations in the shipping industry. With a team of highly qualified and experienced staff, SANCOPACK is committed to providing customers with optimal solutions and the highest quality.

SANCOPACK is providing container lashing and container packing services at the best prices in Ho Chi Minh City, Hanoi, Da Nang, Bac Ninh, Nhon Trach – Dong Nai, Binh Duong, Hai Phong, Quang Ninh.

SANCOPACK ’s container lashing certificate service includes a full range of inspection, design, installation and re-inspection to ensure the safety and durability of the lashing. In addition, SANCOPACK also provides freight-related services such as packaging, loading, unloading, warehousing and transportation to destination.

With a variety of designs and types of containers, SANCOPACK can meet the needs of customers from different industries such as food, chemicals, machinery and equipment, electronics… The products meet international standards and are widely used in import and export activities.

In general, SANCOPACK ‘s container lashing certificate service is an optimal solution for businesses in ensuring the safety of goods during transportation.

Q&A Frequently Asked Questions About Container Lashing – Lashing Container

1. How to Calculate the Number of Boxes in a 20 Feet Container

To calculate the number of boxes that can be contained in a 20-foot container, we need to know the size of the box and the size of the container.

Typically, the size of a crate is determined based on ISO standards. Common crate sizes are 20 feet (6.06m) or 40 feet (12.2m) and the height varies depending on the type of crate.

For a 20-foot container, the typical dimensions of the box are 5.89m x 2.35m x 2.39m. However, to calculate the number of boxes that can be contained in a container, we need to know the dimensions of the specific cargo box.

For example, if the size of the container is 1.2m x 1.2m x 1.2m, we can calculate the number of boxes by dividing the area of the container by the area of the box, and then multiplying this result by the number of boxes stacked on top of each other.

The number of boxes that can be contained in a 20-foot container is calculated using the following formula:

(Number of cartons by length) x (Number of cartons by width) x (Number of cartons by height)

With a cargo box size of 1.2m x 1.2m x 1.2m, we can calculate the number of boxes as follows:

5.89 (container length) / 1.2 (box length) = 4.91 2.35 (container width) / 1.2 (box width) = 1.96 2.39 (container height) / 1.2 (box height) = 1.99

Number of boxes that can be held in a container = 4.91 x 1.96 x 1.99 = 18.27 (this result is rounded down, so a 20-foot container can hold 18 boxes)

In addition, to ensure safety and save space, we should stack the boxes on top of each other. Therefore, the number of boxes that can be stored in a container will depend on the number of boxes stacked and how the boxes are stacked.

With different types of containers, we need to recalculate the number of containers that can be contained in the container based on the size of each type of container.

>> See More: SUPER BAG PP Container Stuffing Airbags

2. How to Calculate the Number of Boxes in a 40 Feet Container

To calculate the number of boxes in a 40-foot container, we first need to know the dimensions of the container and the cargo.

A 40-foot container is approximately 12.2 meters long, 2.44 meters wide, and 2.59 meters high. The volume of a 40-foot container is approximately 67.7 cubic meters.

Cargo boxes usually have a standard size of 1.2m x 1m x 1m. To put the boxes into the container, we need to arrange them horizontally or vertically.

If stacked horizontally, we can stack up to 9 rows and 5 columns. That means the maximum number of boxes that can be stacked in a 40-foot container is 45 boxes.

If stacked vertically, we can stack up to 14 rows and 4 columns. That means the maximum number of boxes that can be stacked in a 40-foot container is 56 boxes.

So to calculate the number of boxes in a 40 feet container, we need to know how to stack the boxes and the maximum number of rows and columns that can be stacked.

3. How to Calculate the Number of Boxes on a Pallet

To calculate the number of boxes on a pallet, we need to know the size of the pallet and the size of each box.

Step 1: Determine pallet size

Pallet dimensions are measured in metres or inches. You need to measure the length, width and height of the pallet. For example, if your pallet dimensions are 1m x 1m x 1m, then the volume of the pallet is 1m³.

Step 2: Determine the size of the box

Knowing the size of the box, we can calculate the volume of each box. The volume of the box is calculated using the formula:

- Volume of the box = Length x Width x Height

For example : if the dimensions of the box are 50cm x 50cm x 50cm, then the volume of the box is 0.125m³.

Step 3: Calculate the number of boxes on the pallet

To calculate the number of boxes on a pallet, divide the volume of the pallet by the volume of each box. For example, if the volume of the pallet is 1m³ and the volume of the box is 0.125m³, we can calculate the number of boxes on the pallet as follows:

Number of boxes on pallet : = Pallet volume / Box volume

= 1m³ / 0.125m³

= 8 boxes

So on a pallet measuring 1m x 1m x 1m and a box measuring 50cm x 50cm x 50cm, we can stack a maximum of 8 boxes.

If you are looking for a reliable and professional partner to pack goods into containers , please contact SANCOPACK for the best advice and support.

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@sancopack.com.vn

| ✅Service: | ⭐Packing wooden pallets, wooden crates, closed & loose wooden crates on site. |

| ✅Price: | ⭐Good price, most competitive |

| ✅Dimensions, load: | ⭕Unlimited |

| ✅Time: | ⭐Committed to completing the project on time. |

| ✅Quality: | ⭐Free consultation, quotation, project survey. |

| ✅Material: | ⭕Pine, acacia, eucalyptus, plywood. |