Preservation of goods

Standard sizes and parameters of wooden pallets in the US market

What Is The Standard Wooden Pallets Size?

Standard pallet sizes often depend on country and industry standardization. However, the most common standard pallet size is 1.2 meters by 1 meter (or about 48 inches by 40 inches) in North America and many other parts of the world. However, there are also other sizes used in some countries or in some specific industries.

Standard Sizes of Pallets

|

48”×40” |

|

|

|

42”×42” |

|

|

|

48”×48” |

|

|

|

40”×48” |

|

|

|

48”×42” |

|

|

|

40”×40” |

|

|

|

36”×36” |

|

|

|

42”×31” |

|

|

|

48”×36” |

|

Other Common Pallet Sizes

The two other most common standard pallet sizes in the United States are:

- 42 x 42 Pallet (Sometimes called “42 Square”)

- 48 x 48 Pallet (Sometimes called “48 Square”)

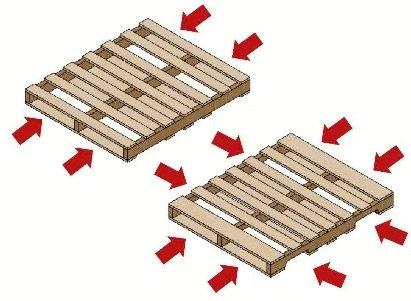

Both types of pallets can be two-way or four-way, indicating the hoisting or lifting point so that the hand truck or forklift can enter in which direction, while the four-way pallet can be seen below.

History Of The 48×40 Standard Pallet

The standard 48” x 40” pallet has been in use since the 20th century, when industry and transportation needed a means to move goods efficiently. The use of wood for pallets grew out of the need for a material that was strong, easily reconditioned, and readily available.

As the industry and transportation industry evolved, the need for standardization in shipping and storage processes led to the establishment of standard pallet sizes. The 48”x40” inch size has become one of the most popular standard sizes due to its ability to accommodate most types of goods and its design.

The 48”x40” inch wooden pallet has become a popular choice for businesses and the shipping industry worldwide. This popularity helps create consistency in the supply chain and shipping of goods.

The use of standard 48”x40” inch wooden pallets has played a vital role in improving supply chain efficiency and management. They help optimize the transportation, storage and handling of goods, thereby reducing costs and enhancing efficiency.:

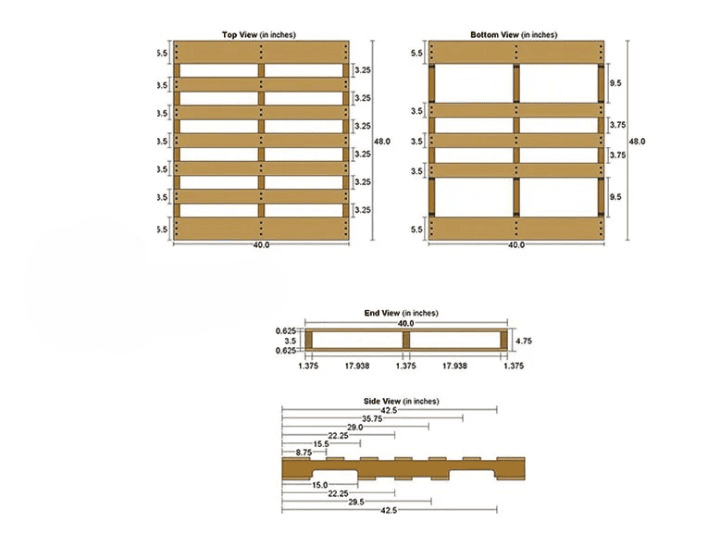

Weight, Height and Load Capacity of Standard Wooden Pallets 48”×40”

A standard pallet is approximately 4 ½ inches high. The top and bottom boards are ½ inch, and the vertical slats are 3 ½ inches high.

The load capacity of a pallet can depend on many factors such as the wood blocks or braces and the number of blocks or braces. However, a standard 48”x40” pallet with 5/8″ thick wood can hold up to 4,600 lbs. This makes it an ideal pallet for grocery or retail stores.

Standard Wooden Pallets Materials

There are many different types of materials used to make pallets, but the main material that is widely used and has good properties and strength is wood. Wood has become the industry standard due to its distinct advantages and suitability for many different applications.

Made from a variety of lumber, these pallets are often used in industries where cost efficiency is a top priority, such as manufacturing, warehousing and logistics. Their durability makes them suitable for carrying heavy loads, including machinery, building materials and bulk cargo.

Wooden pallets can be easily customized in size and overall design to suit specific needs, making them widely applicable. Another advantage is the ability to repair and replace, which prolongs the life of the pallet and saves costs.

Wooden pallets are also often preferred for international shipping, especially when goods need to be stacked securely. They can also be recycled and reused at the end of their life.

There are other alternatives to wood such as plastic and corrugated iron. However, the challenges of using these types of pallets mean that they can only be used in specific situations or suitable industries.

Standard Wooden Pallets Types

Depending on the country and use case, there can be many different variations of the standard pallet. Below are the three basic configurations.

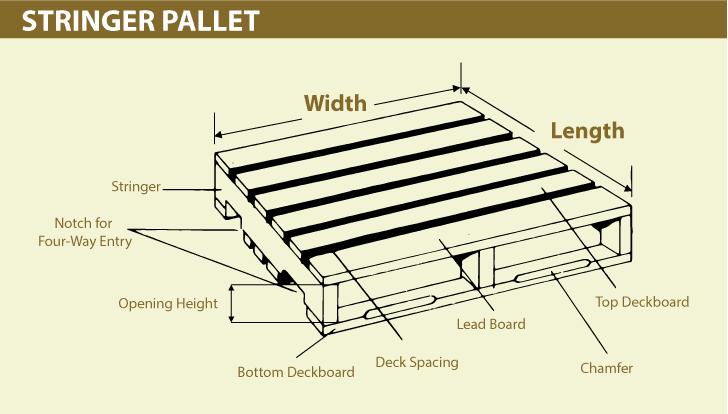

Stringer Pallet

Stringer pallets are a type of pallet that is made from wooden slats, called “stringers”, that run along the length of the pallet to support and lift goods. This is one of the most common and widely used types of pallets in the shipping and storage industry.

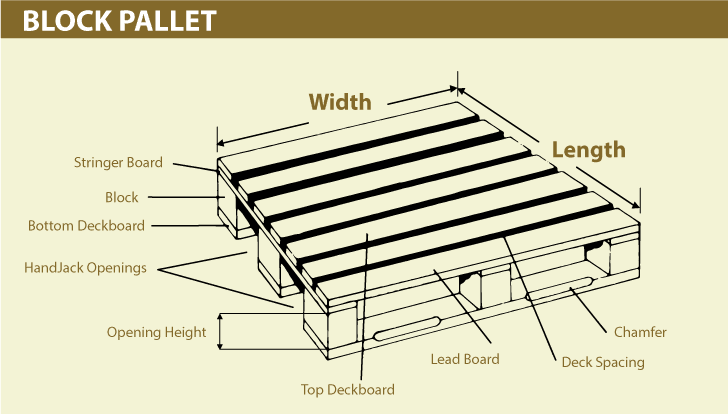

Block Pallet

Block pallet is a type of pallet built with a block structure, usually made from wooden blocks or different block components, instead of using wooden slats like a regular pallet. The main characteristics of block pallets are their strength and durability, especially when subjected to heavy loads or harsh environmental conditions.

The difference from stringer pallets is that they have both top and bottom decks. This design allows for lifting from all sides, making it easier for forklifts to access. Block pallets are generally more durable than stringer pallets.

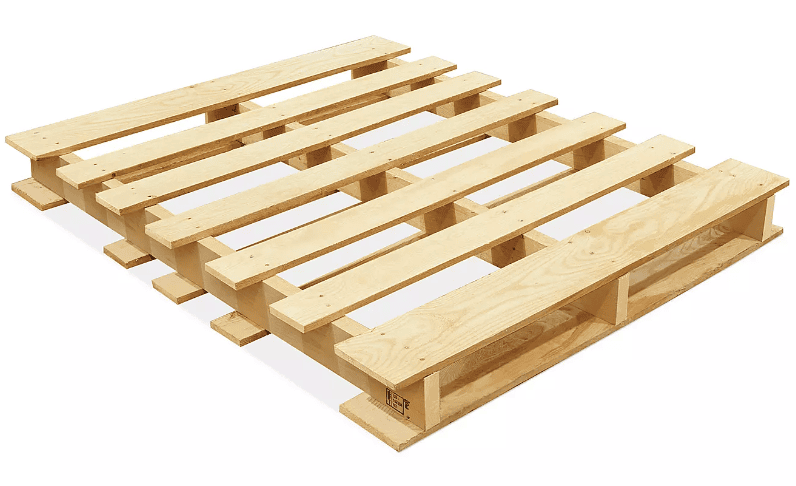

Skid Pallet

Skid pallets are the simplest form of pallet, essentially a single-deck loading platform. What sets them apart from Stringer and Block Pallets is the lack of a bottom deck. Skids are often used for heavy-duty applications and their simple design makes them lightweight and cost-effective.

Standard Pallet (Can Be Customized According To Usage Needs)

A standard pallet can be further modified to meet different needs. These modifications usually occur on the top and bottom deck boards of the pallet.

Solid Deck Pallet

Solid Deck Pallets have no voids or a single hardwood board as the top surface, with no gaps between the boards. This provides a smooth and even surface, ideal for stacking and shipping unstable items. Solid Deck Pallets are often used for bagged products or products with small packaging.

Double Sided Pallet

Double-sided pallets have a top and bottom deck, allowing for more even weight distribution. They come in two types: reversible and non-reversible. Reversible pallets can be flipped and used on either side, while non-reversible pallets have a designated top and bottom. These pallets are suitable for heavier loads and provide more stability during handling.

Winged Pallet

Winged pallets, also known as wing pallets, are pallets designed with “wings” or components that extend out from the sides of the pallet. These wings can be designed to fold or disassemble to create a larger area or to support larger loads.

Double Winged Pallet

Double winged pallet, also known as double wing pallet, is a type of pallet designed with two sides with wings that open wide, creating a larger area for placing goods. Both sides of the pallet have wings that can be opened or folded, depending on the specific needs of transportation and storage.

Methods for Choosing Wooden Pallets Suitable for Your Needs

Many industries, such as the grocery industry, use standard pallet sizes to help improve the efficiency of shipping and distributing their unique products. This has led to a variety of different pallet types being used around the world. Below are some of the most common industry-specific pallets.

Grocery/GMA

Grocery/GMA pallets are standardized pallets primarily used in the grocery industry. With specifications established by the Grocery Manufacturers Association (GMA), these pallets typically measure 48”x40”. They are typically made of wood and are designed to hold a variety of goods such as canned foods, packaged goods, and perishables. The standardized dimensions facilitate efficient handling, storage, and transportation within the grocery supply chain.

GMA Standard Grade A

One of the available options of GMA pallets is Grade A or #1. It is considered the highest quality of recycled pallets. It requires no wire repairs and is dry and free of contaminants according to Food Grade Standards.

GMA Standard Grade B

Another option available for GMA pallets is Grade B, also known as No. 2 pallets. These pallets, which are often worn and discolored, may show signs of brace repairs and block or plug repairs. Grade B pallets are popular due to their lower cost compared to Grade A.

Glass Pallet

Glass pallets are special pallets designed for the transportation and storage of glass products, such as cups, glasses, bottles, and other glass products. Due to the special nature of the goods, glass pallets are often designed to be extremely strong and able to protect the products from impact and damage. Therefore, they are often custom manufactured to fit the specific dimensions and weight of the glass product although the standard size is 56” x 44”.

Can Pallet

“Can pallet” generally refers to pallets used specifically for transporting and storing metal cans (also known as “cans” in English). These cans can contain products such as beverages, canned foods, chemicals, lubricants, and many other types of goods.

Can Pallets still need to be able to support a lot of weight so they are also made of wooden blocks rather than the braces that traditional pallets use. The standard size is 44” x 56” and they usually have a flat, sturdy surface to provide stable support for the cans and prevent them from rolling or becoming damaged.

Beverage Pallet

Beverage pallets are pallets specifically designed for the transportation and storage of beverages, such as soft drink bottles, beverage bottles, beverage cans, and other related products. These pallets are often optimized to meet the specific requirements of the beverage industry, including weight, size, and strength requirements to protect the goods during transportation and storage.

Automotive Pallet

Automotive pallets, or pallets in the automotive industry, are pallets specifically designed for the transportation and storage of automotive components and parts. These pallets are optimized to meet the specific requirements of the automotive industry, including the transportation of large and heavy components such as engines, transmissions, wheels, and other parts. The standard pallet size used in the automotive industry is 48”×45”.

Chemical Pallet

Chemical pallets are used for the storage and transportation of chemical products and due to the hazardous nature of the goods, these pallets are designed to ensure safety, durability and chemical resistance. With standards set in 1991 by the VCI ( Verband der Chemischer Industry ) in Germany and later adopted by EPAL (European Pallet Association), they are typically made from treated wood or sometimes high-density plastic that can withstand corrosion, contamination and harsh conditions. Chemical pallets can also comply with industry-specific standards and regulations to ensure the safe handling and storage of chemical products. To assist different industries in ensuring the selection of appropriate pallets for the transportation of chemicals, standardized sizes and types have been established, each tailored to specific applications and handling needs, from CP1 to CP9. There is also a 48×48 pallet type that is usually only used in the chemical industry – used to store and transport drums.

Reputable and Quality Pallet Suppliers in Ho Chi Minh City, Hanoi, Dong Nai, Hai Phong,….

SANCOPACK is a company specializing in manufacturing and supplying export standard wooden pallets, meeting the requirements of quality and reputation in the packaging and shipping industry.

SANCOPACK Company is committed to providing high quality wooden pallet products at reasonable prices, meeting customers’ needs for packaging and protecting goods during transportation.

SANCOPACK provides various types of wooden pallets, including pine pallets, plywood pallets, and other types of wooden pallets, to meet various requirements from customers.

The company’s pallet products comply with technical standards and regulations, ensuring that goods are packaged and transported safely and efficiently.

The company also provides custom export packing services, ensuring that goods are packed safely and securely to ensure no damage during transit. SANCOPACK has built its reputation in this field through years of experience and commitment to product quality.

Please contact Sancopack immediately via Hotline: 0908105115 to receive the earliest consultation and quote!

See More

- Pine Pallet Packing Service – SANCOPACK Export Pallet Packing Factory

- Wooden Pallet Packing Service, Good Price, Quality

- Wooden Crate Packing Service Good Price, Reputable, High Quality

- Export Packing Service On Demand, On-Site

- Export Standard Wooden Pallet Manufacturing Company , Reputable, Professional, Cheap Price In Ho Chi Minh City, Hanoi – SANCOPACK

- Wooden Pallet Factory According to Demand in Hanoi Cheap Price – Export Standards

- Wooden Pallet Factory According to Demand in Ho Chi Minh City, Cheap Price, Quality

- Where to Buy Cheap Wooden Pallets in Binh Duong – Reputable, High Quality Wooden Pallet Manufacturing Factory

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@vietnamtravelcard.vn.vn

| ✅Service: | ⭐Wooden pallet packing service, wooden crate packing, wooden crate packing, closed & open wooden crate packing on site. |

| ✅Price: | ⭐Good price, most competitive |

| ✅Dimensions, load: | ⭕Unlimited |

| ✅Time: | ⭐Committed to completing the project on time. |

| ✅Quality: | ⭐Free consultation, quotation, project survey. |

| ✅Standard: | ⭐ISPM 15, ISO 9001:2015,..EU, USA. |

| ✅Material: | ⭕Pine, acacia, eucalyptus, plywood. |