Preservation of goods

Structure And Loading In Reefer Container

Refrigerated containers, also known as reefer containers, are specialized containers designed to maintain a stable temperature during the transportation of perishable goods such as food, pharmaceuticals and agricultural products. Different from ordinary containers, refrigerated containers have a special structure and strict requirements on how to stack goods to ensure effective cooling and safety for goods.

What is a Reefer Container?

Refrigerated Container (or Reefer Container) is a type of container designed to maintain a stable temperature during transportation or storage. The temperature can be adjusted according to needs, usually from -30°C to +30°C, there are even specialized types for super-cold goods at -60°C.

Reefer containers usually come in two common sizes:

- 20 feet refrigerated container

- 40 feet refrigerated container

Depending on the purpose of use, businesses can choose the type of container suitable for their products.

>>> See More : Pallet Leg Lock in Reefer Container – Reefer lock

Structure of Refrigerated Container

Frame and Shell

Refrigerated containers typically come in standard sizes such as 20 feet or 40 feet, with frames made from high-strength steel for durability and load-bearing capacity. The outer shell is made from stainless steel or aluminum, which helps prevent corrosion and protects the insulation inside.

Insulation Layer

Insulation is an important factor in maintaining the temperature inside the container. Polyurethane foam (PU) or vacuum insulation panels (VIPs) are often used for insulation. The thickness of the insulation can be up to 100 mm, helping to minimize heat transfer between the outside environment and the inside of the container.

Cooling System

The refrigeration system is integrated in the front of the container, including the compressor, condenser and evaporator. This system operates continuously to maintain the set temperature, which usually ranges from -30°C to +30°C, depending on the requirements of the goods.

Container Floor

The refrigerated container floor is designed in an aluminum T-floor form , allowing cold air to circulate evenly throughout the storage compartment. This design also supports easy cleaning and quick drainage.

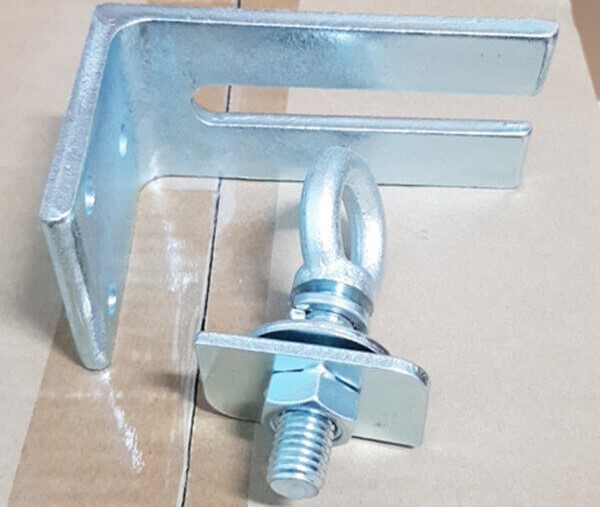

Lashing System

In refrigerated containers, there are usually 8 lashing points on the bottom of the container floor to help fix goods quickly, but the load-bearing capacity of these lashing points is not too high.

To solve that problem, Sancopack has developed the reefer container leg lock, a flexible anchor point system that is attached to the reefer container floor and can be adjusted in position according to needs to help secure goods safely during transportation.

Operating Principle of Reefer Container

When the reefer container is supplied with electricity (from a ship, truck, or generator), the refrigeration system operates in a cycle:

- The compressor compresses the refrigerant into high pressure gas.

- The condenser cools the gas and converts it to liquid.

- The evaporator absorbs heat from the cargo hold → lowers the temperature.

- The fan blows cold air evenly throughout the container.

The temperature is maintained continuously at the preset level.

Instructions for Loading Goods in Reefer Containers

Ensure Air Circulation

The cold air flow in the container needs to be circulated evenly to maintain a stable temperature. Therefore, when loading goods, it is necessary to leave space between the packages and between the goods and the container walls. Do not stack goods close to the ceiling or floor of the container to avoid blocking the cold air flow.

Use of Cargo Fixing Devices

To prevent goods from shifting during transport, it is necessary to use securing devices such as dunnage bags and lashing straps . Using the right type of equipment and following the goods securing procedure will minimize the risk of damage to the goods and ensure the safety of the operator.

Compliance with Weight Regulations

Before loading, check the maximum allowable load of the container and ensure that it does not exceed this limit. Distributing the weight of the goods evenly throughout the container also helps maintain balance and stability throughout the journey.

Applications of Reefer Containers in Practice

Reefer containers are widely used in:

- Transporting fresh food (vegetables, fruits, meat and fish)

- Export of frozen seafood

- Storage of vaccines and medical drugs

- Agricultural export industry such as durian, dragon fruit, mango

For goods requiring strict temperature control, refrigerated containers are an irreplaceable choice.

Some Notes When Using Refrigerated Containers

- Before loading : Always check the operating status and set the correct required temperature.

- Do not block airflow : Make sure cargo does not block fans or airflow.

- Temperature monitoring : Use a data logger or remote monitoring if traveling long distances.

- Clean after each shipment : Avoid mold and bacteria residue.

Sancopack is a reputable and quality supplier of cold container foot locks in HCM, Hanoi, Binh Duong, Dong Nai,…

With many years of experience, we are trusted and highly appreciated by customers nationwide for the quality of our services. Professional technical and consulting team, 24/7 customer support. If you need to order or need a product quote, please contact Sancopack immediately via Hotline: 0908105115 to receive the earliest advice and quote.