Preservation of goods

VCI Metal Corrosion Inhibitors? Where to buy?

What Are the Consequences of Metal Corrosion?

Corrosion of metals can have many significant consequences. In terms of safety, corrosion damage can cause fires, explosions, toxic gas leaks, and building collapse. In terms of health, the products of metal corrosion can pollute and affect human health.

Corroded metals also deplete natural resources, including the metals and fuels used to produce the metals. In addition, corroded materials are often aesthetically unpleasing, making them difficult to look at and use.

What Substances Corrode Metal?

Corrosion is the process of destruction of metals or alloys due to environmental influences such as acids, salts, chemicals and other factors. When metals come into contact with corrosive substances, they can be worn, oxidized, or chemically reacted, leading to a reduction in the strength and properties of the material.

Common corrosive chemicals to metals include sulfuric acid (H2SO4), nitric acid (HNO3), hydrochloric acid (HCl), acetic acid (CH3COOH), and alkalis such as NaOH (sodium hydroxide) and KOH (potassium hydroxide). In addition, salts and other chemical compounds can also corrode metals.

>>> See More : VCI SMP Rust-X Anti-Rust Technology Takes Immediate Effect And Lasts Up To 15 Years

How to Prevent Metal Corrosion?

Currently, there are some commonly used methods of metal corrosion prevention such as:

1. Metal surface coating : Coating can protect metal from direct contact with corrosive environments.

2. Electroplating : The electroplating process helps create another metal coating on the metal surface, providing protection against corrosion.

3. Use corrosion-resistant alloys : Some alloys have better corrosion resistance than the base metal, so using this alloy can minimize the corrosion process.

4. Use of anti-corrosion agents : Anti-corrosion agents such as coatings and anti-corrosion solutions can be used to protect metals from environmental impacts.

However, the best corrosion protection method will depend on the type of metal, the environment and the specific requirements. Advice and selection of corrosion protection methods should be carried out by experts or engineers who specialise in materials and metal corrosion.

VCI Metal Corrosion Inhibitor – Easy to Use for Any Metal Product

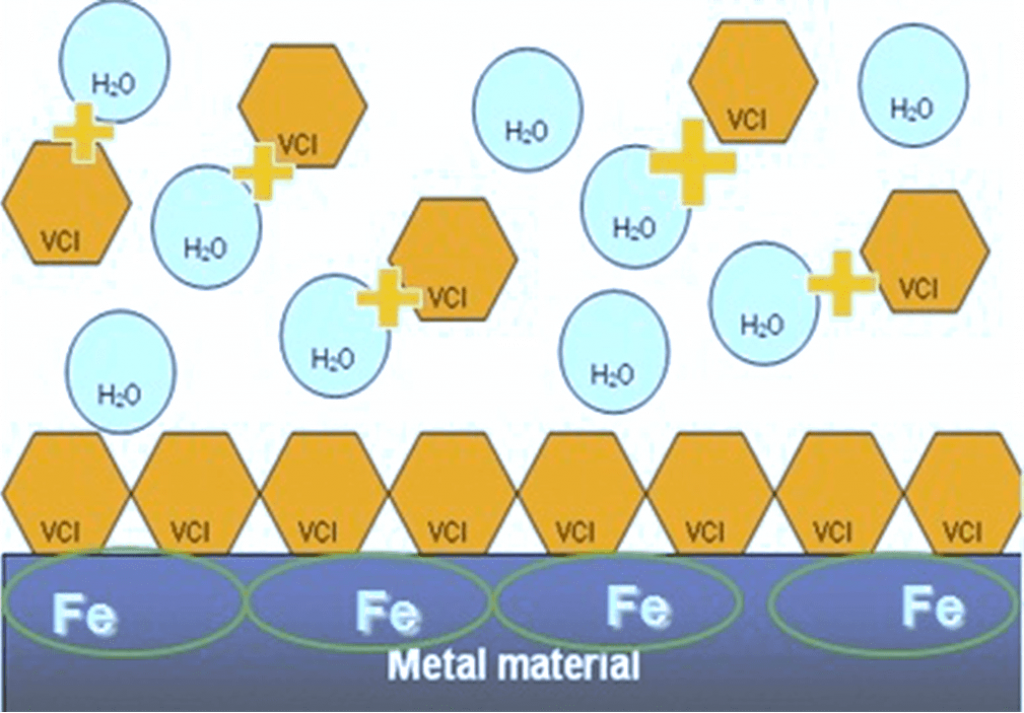

VCI SMP Metal Corrosion Inhibitor is a type of metal corrosion inhibitor used to protect metal products from corrosion and moisture. VCI stands for “volatile corrosion inhibitor”, and SMP (Speedy Moisture Passivation) is a technology that quickly removes moisture to provide absolute corrosion protection for metal surfaces.

VCI SMP Metal Corrosion Inhibitor works by releasing corrosion inhibitors into the space surrounding the metal.

These substances form a protective coating on the metal surface, preventing contact with air, moisture and other corrosive agents. This helps to prolong the life of metal products and minimize the effects of corrosion.

Benefits and Applications of VCI Metal Corrosion Inhibitor

VCI SMP is a technology used to prevent and protect metals from corrosion. It offers many applications and benefits, including:

- Metal Protection : VCI SMP is designed to protect various metals, including steel, iron, aluminum and copper, from corrosion. It forms a protective film on metal surfaces, inhibiting corrosion reactions caused by moisture, oxygen and other environmental factors.

- Long Term Protection : VCI SMP provides long lasting corrosion protection, even under harsh conditions. It can prevent corrosion during storage, transportation or in outdoor environments.

- Self-healing mechanism : One of the significant benefits of VCI SMP is its self-healing ability. If the protective coating is damaged or disrupted, the VCI particles will re-disperse and form a new protective layer, ensuring continuous corrosion protection.

- Ease of Use : VCI SMP can be applied in a variety of forms, including powders, emulsions, coatings, films or as an additive in packaging materials. It is easy to use and can be integrated into existing manufacturing processes.

- Environmentally Friendly : VCI SMP technology is environmentally friendly compared to traditional corrosion prevention methods. It eliminates the need for the use of toxic chemicals or oils, making it a safer option for both the user and the environment.

- Versatility : VCI SMP is suitable for a wide range of industries and applications, including automotive, aerospace, electronics, metalworking, marine and more. It can be used to protect components, machinery, equipment, structures and other metal surfaces.

The Best VCI Metal Corrosion Protection Products

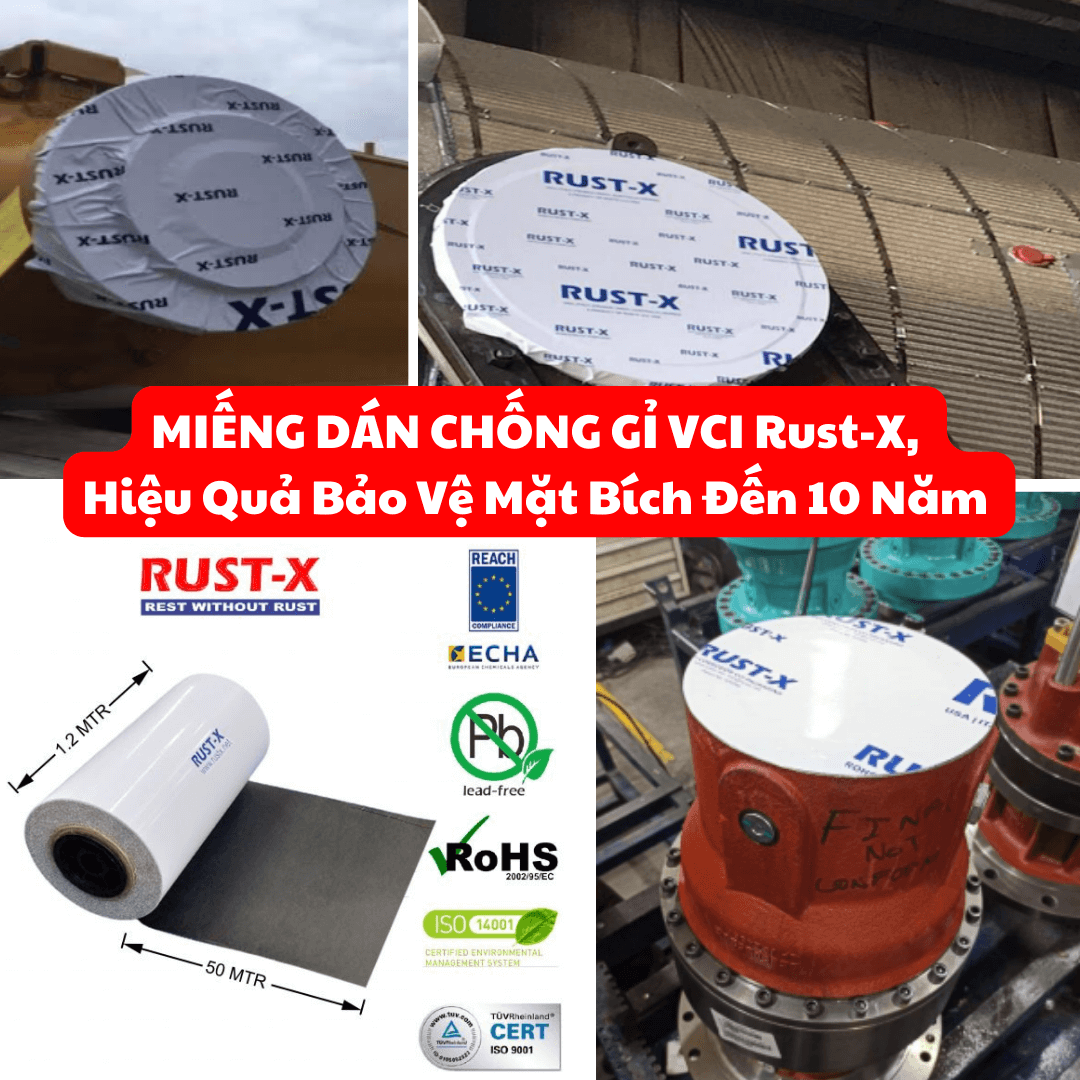

1. VCI Anti-Rust Sticker

VCI Sticker is a product used to prevent corrosion and protect the surface of metal parts.

It is designed to protect corrosion-prone surfaces without the need for physical paint or oil. These stickers are easy to apply and remove, leaving no residue on metal surfaces.

VCI Stickers use VCI (Vapor Corrosion Inhibitor) technology, which helps prevent rust and corrosion by releasing chemicals that create a protective layer on metal surfaces.

>>> See More: How to Protect Flanges from Rust and Corrosion in 1 Simple Step

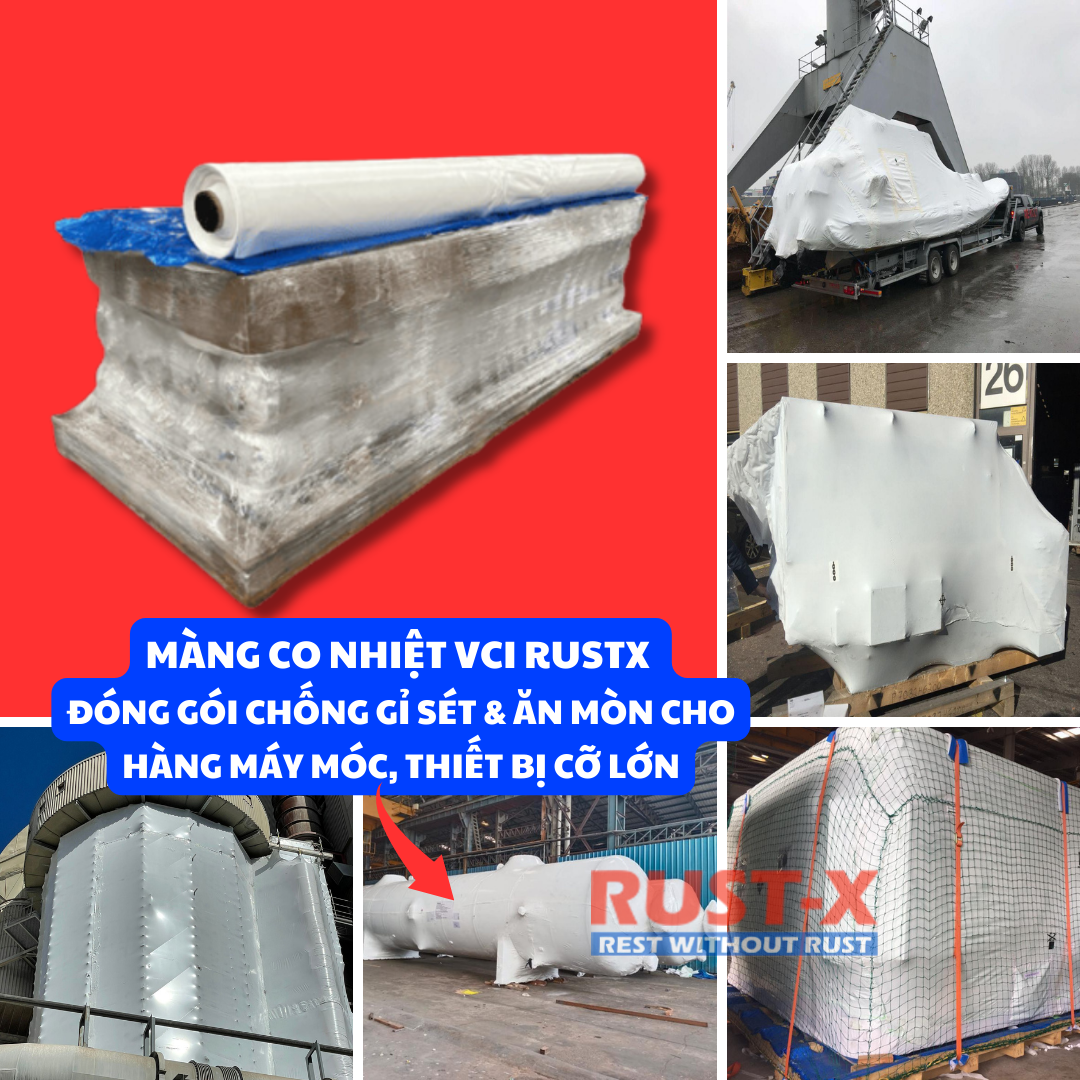

2. VCI Anti-Rust Heat Shrink Film

VCI thermal insulation is a protective packaging material used to prevent rust and corrosion on metal surfaces. It is designed to provide a barrier against moisture, dirt and other contaminants that can cause corrosion. When VCI thermal insulation is heated with a heat gun, it adheres tightly to the surface of the product, forming a protective layer.

>>> See More: VCI Heat Shrink Film for Packaging and Anti-Rust for Large Machinery and Equipment

VCI thermal films contain vapor corrosion inhibitors that are released when the film is torched. These inhibitors create a protective layer on the metal surface, preventing the formation of rust and corrosion. The films are commonly used to package and protect metal products during storage and transportation.

See More:

- What is Metal Rust Remover? Which Type is Good? Where to Buy?

- Top 6 Most Popular Anti-Rust Oils in the Metalworking Industry

- What Is The Best Anti-Rust Solution? Where To Buy?

- VCI Metal Corrosion Inhibitor? Where to Buy?

- Anti-Rust Spray For Motorcycles? Which Type Is Best? Where To Buy?

- What Are the Advantages and Limitations of Different Metal Corrosion Prevention Methods?

- 15 Ways to Prevent Rust That You Shouldn’t Miss

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@vietnamtravelcard.vn.vn

| ✅VCI Anti-Rust: | ⭐VCI anti-rust film, VCI anti-rust paper, anti-rust bag, anti-rust spray, VCI anti-rust oil |

| ✅Effective: | ⭐Anti-rust 5 – 10 years |

| ✅Trademark: | ⭕Rust-X (USA) |

| ✅Certification: | ⭐ ROHS, ISO 9001, ISO 14001, Confirm MIL & DIN Standards, Pass VIA |

| ✅ Phone: | ⭐ 0908105115 |