Preservation of goods

What Are The Different Methods Of Metal Corrosion Resistance?

In fact, metal materials are often affected by corrosion and rust over time. This reduces the durability and lifespan of metal products, structures and systems.

However, there are various metal corrosion prevention methods used to protect metals from this phenomenon.

What Are The Best Methods To Prevent Metal Corrosion Today?

Each method has its own advantages and limitations, depending on the specific requirements and conditions of each application.

>>> See More : Intercept Anti-Rust Film – Perfect Anti-Rust Technology For Goods

1. Anti-corrosion paint for metal

Anti-corrosion paint for metals is a common method used to protect metals from corrosion.

The advantage of anti-corrosion paint is the ability to create a strong protective layer on the metal surface, preventing corrosion from the environment. In addition, paint can also increase the aesthetics and increase the life of the metal.

However, the drawback of anti-corrosion paint is that it takes time and effort to prepare the surface before painting, and the paint can peel if not properly stored and used.

2. Anti-rust metal plating

Metal plating is the process of coating a metal surface with another metal layer to protect it from corrosion.

The advantage of metal plating is that it creates a strong and durable protective layer, enhancing the strength and corrosion resistance of the base metal.

In addition, metal plating also has the ability to improve aesthetics and help protect against impact and scratches.

However, the limitation of this method is high cost and complex plating process, requiring high technique.

3. Use corrosion resistant materials

Using corrosion-resistant materials is another method of preventing metal corrosion. Corrosion-resistant materials include metals such as stainless steel, aluminum alloys, or chemical-resistant plastics.

The advantage of corrosion resistant materials is that they have been designed to resist environmental corrosion and are highly durable.

They provide superior corrosion resistance and long service life to metals. Furthermore, corrosion resistant materials have good resistance to pressure and impact.

However, the limitation of this method is that corrosion resistant materials can be more expensive and are not suitable for all applications.

Additionally, replacing and repairing damaged components can also be costly.

4. Anodizing system

Anodizing is the process of creating a protective oxide layer on the surface of a metal through an electrochemical reaction. The advantage of anodizing is that it creates a hard and durable protective layer on the metal surface, increasing the corrosion resistance and improving the beauty of the metal.

The anodizing process can also produce a wide range of colors and aesthetic effects on metal surfaces.

However, the limitation of this method is that the anodizing process is complicated and requires high technique. In addition, it is only applicable to certain metals such as aluminum and titanium.

5. Sand protection system

The carburizing protection system is a method of preventing metal corrosion used in aqueous environments. The process involves creating a carburizing voltage on the metal surface to prevent corrosion.

The advantage of the sandblasting protection system is that it provides a strong protective layer, does not change the original metal structure and does not affect its physical properties.

However, this process requires a complex system to generate the sanding voltage and maintain it during operation. In addition, the effectiveness of the sanding protection system can be affected by environmental factors such as pH, temperature, and the content of corrosive substances in the water.

In fact, there are many different metal corrosion prevention methods available depending on the specific requirements and conditions of each application.

Each method of metal corrosion protection has its own advantages and limitations, and choosing the appropriate method depends on many factors such as finances, environmental properties, operating requirements and desired metal life.

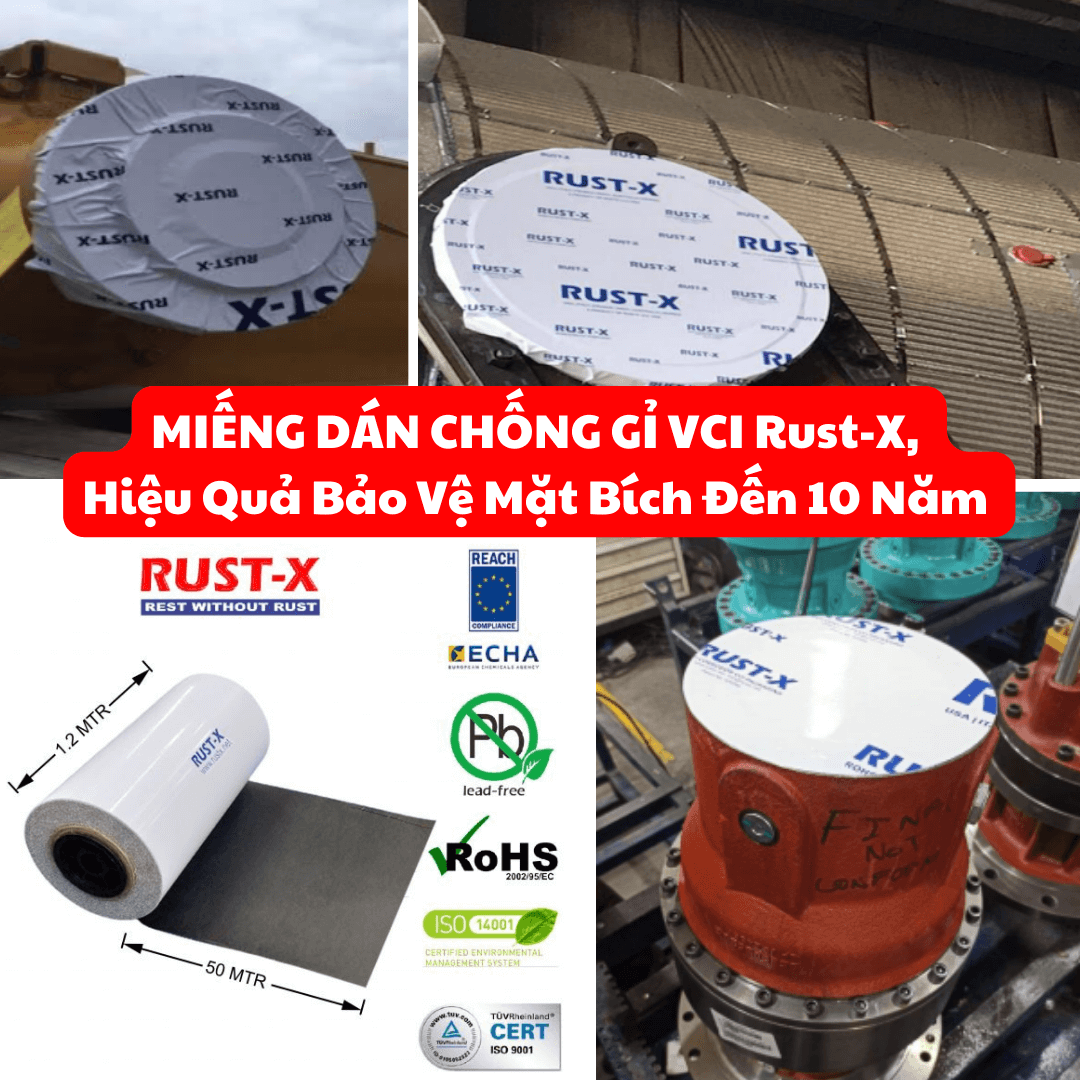

Introducing VCI Anti-Corrosion Technology

Volatile Corrosion Inhibitor (VCI) is an effective method to protect metals from corrosion. VCI is widely used in industry for the preservation and transportation of metal products.

VCI works by releasing non-volatile chemical compounds into the surrounding environment.

These compounds form a protective film on the metal surface, preventing contact between the metal and the corrosive environment.

This film not only protects the contact surface but can also spread and protect other parts of the metal in the near space.

The advantages of VCI metal anti-corrosion technology are:

- Effective and convenient : VCI is an effective and easy-to-apply anti-corrosion method. There is no need for direct contact with the metal or the use of complex coatings.

- Comprehensive protection : VCI is capable of protecting not only the contact surface but also other parts of the metal in the near space, helping to prevent corrosion from all directions.

- Easy to reuse : VCI can be reused for multiple metal storage or transportation operations without the need to replace or renew the protective layer.

>>> See Details: SMP RustX VCI Anti-Rust Paper

However, VCI metal anti-corrosion technology also has some limitations:

- Duration of action : The effectiveness of VCI depends on the duration of contact with the metal. Protection may be limited if sufficient contact time of VCI with the metal is not ensured.

- Environmental stability : Certain environmental conditions such as high temperature, increased humidity can affect the effectiveness of VCI.

- Depends on VCI quality : The quality and composition of VCI can affect the effectiveness of metal protection. VCI quality must be guaranteed to ensure its stability and effectiveness. If VCI is not of the required quality, it may not provide enough anti-corrosion compound or not evaporate properly, resulting in reduced effectiveness.

- Metal type limitations : VCI metal corrosion protection technology can be effective against different types of metals. VCI may work well on some metals such as stainless steel, aluminum, iron, but may not be effective on other metals. Therefore, it is necessary to clearly identify the type of metal that VCI is used to protect against corrosion.

- Cost : Some types of VCI can be more expensive than other corrosion protection methods. This can be a limitation to the use of VCI metal corrosion protection technology in some applications.

In summary, VCI metal anti-corrosion technology is an effective method to protect metals from corrosion. It has the advantages of efficiency, convenience and comprehensive protection.

However, it also has limitations in terms of impact time, environmental stability, VCI quality, metal type limitations and cost. But compared to the cost of risk and loss when rust damage will be much cheaper.

Q&A Frequently Asked Questions About Metal Corrosion Prevention

1. How to choose the right metal corrosion protection method for your application?

When choosing a method of metal corrosion protection , many factors must be considered such as environmental properties, operating requirements, finances and the desired life of the metal.

Evaluate the advantages and limitations of each method, and consult with experts in the field to make the best decision for your application.

2. What other corrosion prevention measures are there besides applying anti-corrosion methods?

In addition to applying anti-corrosion methods for metals, preventive measures can be taken such as regular maintenance, servicing and periodic inspection of metal surfaces, reducing the impact of corrosive factors such as chemicals, high temperatures, humidity and pressure, using surface protection such as enamels or organic polymer coatings, ensuring ventilation and providing effective drainage systems.

At the same time, ensure timely maintenance and repair to fix small problems before they spread and cause major damage.

3. Why is it necessary to protect metal materials from corrosion?

Corrosion protection is an important process to protect and extend the life of metallic materials. Corrosion and rust can weaken the structure and properties of metals, reducing the durability and life of products, structures and systems.

By applying metal corrosion prevention methods, we can prevent or minimize the impact of the environment and maintain the properties and performance of metals over a long period of time.

4. What factors affect metal corrosion?

There are many factors that can influence metal corrosion, including the pH of the environment, the concentration of corrosive agents, humidity, temperature, pressure, and mechanical stress. Each of these factors can act individually or in combination to influence the corrosion process and the rate of metal deterioration.

5. Are there any metal corrosion prevention methods that are particularly suitable for marine environments?

In seawater environments with high salt concentrations, one of the common methods of corrosion prevention is to use a carburizing protection system. This method creates a carburizing voltage on the metal surface to prevent corrosion.

Additionally, using corrosion-resistant materials such as stainless steel or aluminum alloys can be a good choice, as they are more resistant to corrosion from salt and seawater than other metals.

6. What are some effective preventive corrosion measures?

To prevent metal corrosion , a number of preventive measures can be taken, including:

- Ensure good engineering design of metal products to minimize environmental impact.

- Use corrosion-resistant materials or apply protective methods such as anti-corrosion paint or metal plating.

- Ensure effective ventilation and drainage in the system to reduce the effects of humidity and pressure.

- Perform regular inspections and maintenance to detect corrosion problems early and replace or repair promptly.

- Reduce exposure to corrosive agents by using enamels or organic polymer coatings.

7. Is there a method that combines aesthetics and corrosion resistance for metal?

Anti-corrosion painting method for metal is one of the methods that combine aesthetics and anti-corrosion for metal. Anti-corrosion painting not only creates a strong protective layer but also improves the aesthetics of the metal.

There are many types of anti-corrosion paints available in the market with various colors and effects. Choosing the right paint not only provides protection to the metal from corrosion but also creates an attractive and aesthetic surface.

8. Are there any special anti-corrosion methods suitable for fluid pipes?

For fluid pipes, a common method of preventing metal corrosion is to use an internal protective layer.

This may include the use of metallic plating, polymer coatings or enamels to provide a corrosion and impact resistant surface. These internal protective layers help protect the pipe from corrosion and extend its life in the application environment.

9. What factors should be considered when selecting a corrosion protection method for a particular application?

When selecting a metal corrosion protection method for a particular application, the following factors should be considered:

- Environmental properties : Evaluate pH, corrosive concentrations, temperature and pressure in the application environment.

- Operational Requirements : Consider the requirements for durability, longevity, aesthetics and performance of the metal in the specific application.

- Finance : Evaluate the cost of implementing and maintaining the anti-corrosion method .

- Feasibility : Consider the feasibility of implementing and implementing the metal corrosion prevention method within the available conditions and resources.

See More:

- What is Metal Rust Remover? Which Type is Good? Where to Buy?

- Top 6 Most Popular Anti-Rust Oils in the Metalworking Industry

- What Is The Best Anti-Rust Solution? Where To Buy?

- VCI Metal Corrosion Inhibitor? Where to Buy?

- Anti-Rust Spray For Motorcycles? Which Type Is Best? Where To Buy?

- What Are the Advantages and Limitations of Different Metal Corrosion Prevention Methods?

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@vietnamtravelcard.vn.vn

| ✅VCI Anti-Rust: | ⭐Anti-rust plastic film, anti-rust paper, anti-rust bag, anti-rust spray, VCI anti-rust oil |

| ✅Effective: | ⭐Anti-rust 5 – 10 years |

| ✅Trademark: | ⭕Rust-X (USA) |

| ✅Certification: | ⭐ ROHS, ISO 9001, ISO 14001, Confirm MIL & DIN Standards, Pass VIA |

| ✅ Phone: | ⭐ 0908105115 |