Preservation of goods

Methods Of Packaging And Preserving Coconut For Export

The way of packaging coconut for export has a great influence on the efficiency and quality of product preservation. Currently, there are many different ways to package and preserve coconuts to achieve the highest efficiency.

To learn more about how to pack coconuts for export as well as how to preserve agricultural products for export, let’s find out with Sancopack through the article below!

Opportunity To Export Fresh Coconut To European Market

Currently, Vietnam has the opportunity to export fresh coconuts to Europe, helping to expand the consumption market and increase the export value of agricultural products.

According to information from sources on the search page, many businesses in Vietnam are ready to meet the FDA’s phytosanitary and food safety requirements. This requires ensuring the quality and origin of fresh coconut products before being exported.

Thus, the opportunity to export fresh coconuts from Vietnam to Europe is becoming attractive and potential. This not only helps expand the market for Vietnam’s agricultural industry but also creates opportunities to promote economic development and create jobs in the agricultural sector.

How to Ensure the Quality of Coconuts Exported to Europe

To ensure the quality of fresh coconuts for export, businesses need to comply with strict standards and procedures. Here are some ways to ensure the quality of fresh coconuts during the export process:

- Selecting Quality Raw Materials : Businesses need to select fresh coconuts from growing areas that are reputable for quality. Selecting input materials ensures that the final product will meet standards for shape, size and color.

- Traceability and Production Control : Track the origin and production process of fresh coconuts from planting, care, harvesting to packaging and transportation. Ensure that crop care methods and production processes comply with food safety regulations.

- Food Safety Assurance : Ensure that fresh coconuts are handled and packaged according to food safety and hygiene procedures. This includes the use of clean equipment and work environments to avoid the risk of contamination.

- Phytosanitary and Quality Control : Before export, fresh coconuts need to be inspected for quality and phytosanitary control by the competent authorities. This ensures that the product meets the import requirements of the destination country.

- Professional Packaging : Use professional packaging methods to ensure that fresh coconuts are not damaged during transportation. Packaging needs to be durable, shockproof and protect the product from loss.

Supply Chain Tracking: Track your product’s supply chain from the grower to the consumer. This helps to detect and resolve issues as they arise, ensuring that your product always meets quality standards.

Export Coconut Packaging and Preservation Process

The process of packaging and preserving coconuts for export requires careful preparation to ensure that the quality of the coconuts is maintained throughout the transportation and storage process. Below are the basic steps in the process of packaging and preserving coconuts for export:

Measures for harvesting and preserving coconuts

The fruit is harvested when the coconut is in its 8th month, the fruit clusters are then transported to the processing site, stacked in piles to create gaps between the fruits for ventilation.

The fruit should be processed as soon as possible. During the period before processing, it is necessary to store raw coconut in a cool place or/and use fans to maintain ventilation depending on the ventilation of the storage place. Creating ventilation is to reduce the intensity of natural respiration of the fruit and avoid the phenomenon of water condensation (due to respiration) on the surface of the fruit leading to fruit damage.

Prepare the fruit and peel it

- Fruit preparation: the fruit is cut out of the bunch, at the same time removing unqualified fruit and stacking them in a pile. Unqualified fruit is what is popularly called “deaf fruit”, meaning it has no water inside and feels light when picked; fruit eaten by insects or rats; fruit that is deeply bruised due to picking or transport.

- Peeling process: 2 peeling stages: chop 2 ends and 3 cuts lengthwise of the coconut then peel to the desired shape, pyramid shape and round tip shape.

Fruit surface treatment

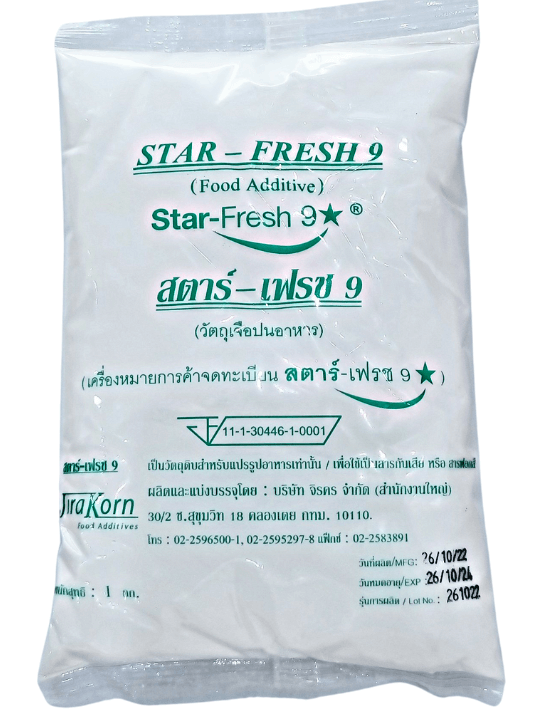

After being peeled, the coconut will be whitened with star fresh 9 food additive to whiten the coconut to help the quality of the coconut be uniform and increase the aesthetics. Then we soak and dip the coconut in preservatives provided by Sancopack to kill fungus and increase the resistance of the fruit. Then the fruit will be dried and packaged.

Dry the fruit surface

If the quantity is small, to save costs, we can use industrial fans to dry. If for export, we should use a drying line to save time and improve efficiency.

Carton packing

After being dried, the fruit is placed in a 2-layer carton and wrapped with shrink film to ensure that the fruit is not damaged during transportation.

Cold storage

The fruit crates are kept in cold storage or in refrigerated containers if transported by sea. The internal temperature is 1 – 4ºC.

Standards for Packaging and Preserving Exported Coconuts

1/ Standards on pesticide residues

Fresh coconuts for export must ensure that pesticide residue levels do not exceed the regulations of the importing market. In addition, contaminants such as pesticides and heavy metals must be controlled.

2/ Standards for fresh coconut quality

There is no official standard for the quality of fresh coconuts for export. Because depending on each export market, the quality standards will be different. However, basically, fresh coconuts still need to ensure some basic standards as follows:

- Fresh coconut intact and not scratched

- Clean, no visible external issues

- No harmful pests, no strange smell or taste on the outside

- The outside humidity should not be erratic.

3/ Standards on packaging size and specifications

Normally, fresh coconuts for export will be packed in sacks or jute bags. Then the coconuts will be placed in cartons for transportation. Each carton will weigh about 25kg, equivalent to more than 20 coconuts. If the coconuts are young, the shell can be peeled into a diamond shape before packing. The size of the carton containing the coconuts is determined based on the weight of the fruit (can refer to ASEAN standards).

4/ Regulations on post-harvest coconut treatment

After harvesting, fresh coconuts need to be properly processed. Regulations for processing fresh coconuts for export after harvest are as follows:

- Avoid sudden temperature changes of 8ºC or more

- The best temperature for storing and preserving fresh coconuts is from 0 – 16ºC. Mature coconuts are usually transported at 8ºC – 12ºC. Young coconuts can be stored at 3ºC – 6ºC. High temperatures will significantly reduce shelf life.

- Maintain humidity around 80% for mature coconuts and 90% for young coconuts to prevent coconut from losing weight and evaporating.

Some Notes When Packaging and Preserving Exported Coconuts

Depending on the market where fresh coconuts are exported, the fresh coconut shipment will be required by the buyer to be packaged and transported in a refrigerated container at a suitable temperature to avoid damaging the fresh coconut shipment. Currently, there are two popular types of fresh coconut exports: Whole coconuts and Diamond coconuts.

- Whole coconuts are transported in refrigerated containers, with an average temperature of 0ºC, ventilation of 10, and humidity of 50-60%.

- Diamond-cut coconuts are packed into containers according to the following specifications: temperature maintained above 2 degrees Celsius, ventilation is 10, and humidity is 50 – 60%.

Recommended Specifications for Packing Coconut for Export

| Optimal Temperature During Transport | 0°C to 1,5°C |

| Maximum Cold Temperature | -0,9°C |

| Temperature To Be Exposed During Packing | Max. 2°C above carrying temperature |

| Humidity | 75% to 85% |

| Ventilation | 5 m3/hr |

| Shelf Life | 2 months |

| Hyperventilation/Normal Breathing | Normal Breathing |

| Ethylene Production Rate | Very Low |

| Ethylene Sensitivity | Fruit does not produce ethylene |

| Atmosphere is regulated/controlled | |

| Potential | Normal |

Sancopack Specializes in Providing Agricultural Product Preservation Solutions for Coconut Export

With over 24 years of experience in the field of packaging and preserving goods, Sancopack specializes in providing solutions such as: Natacoat (antifungal), Kadozan (increasing fruit resistance), ethylene absorbers, ethephon (ripening fruit), oxygen absorbers, oxygen bags, star fresh 9….

If you are looking for solutions to preserve agricultural products for export, please contact Sancopack immediately via Hotline: 09108105115 for advice and quotation.

See More:

- Top 12 Best Food Preservation Methods Today

- Top 11 Methods of Preserving Fruits and Vegetables After Harvest

- AnsiP 1-MCP Agricultural Product Preservation

- GreenMAP Bags Keep Vegetables And Fruits Fresher And Longer

- How to Preserve Fresh Longan After Harvest for Up to 30 Days

- Ways to Preserve Agricultural Products After Harvest to Export Standards

- The Fastest And Easiest Way To Preserve Fruit In Business?

- Natacoat Anti-Mold Preservation For Fruits And Vegetables

- Detailed Instructions on How to Preserve Oranges Fresh for a Long Time and Safely

- Ethephon Safe Fruit Ripening Agent

- KADOZAN Biological Product (Chitosan Content 2%)

- SUPER FRESH Ethylene Absorbent Bag

- Ethylene Absorber In Cold Storage For Vegetables And Fruits

- Ethylene Absorber AS Filter Tubes

- How to Preserve Fresh Ginger for a Long Time, Prevent Mold – Ensure Export Standards to the US and Europe

- How to Preserve Fresh Pineapple for Long-distance Export

- HOCl Solution for Preserving Fruits and Food

- How to Preserve Fresh Phalaenopsis Orchids for Long-distance Transport and Export

- Instructions on How to Harvest and Preserve Avocados to Ripen Long Effectively

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@vietnamtravelcard.vn.vn

| ✅ Preserving vegetables and fruits: | ⭐ Absorbs ethylene, anti-mold, disinfects, prevents dehydration. |

| ✅ Effectiveness: | ⭐ Keeps fresh for longer, reduces damage, slows ripening & aging. |

| ✅ Standards: | ⭕ Food safety, US FDA |

| ✅ Biological products: | ⭐ Chitosan, 1-MCP, MAP, Natamycin |

| ✅ Certification: | ⭐ Full quality certification. |