Preservation of goods

Preservation of agricultural products after harvest by atmospheric control method in refrigerated containers

Preserving organic produce and transporting it internationally by sea is very difficult.

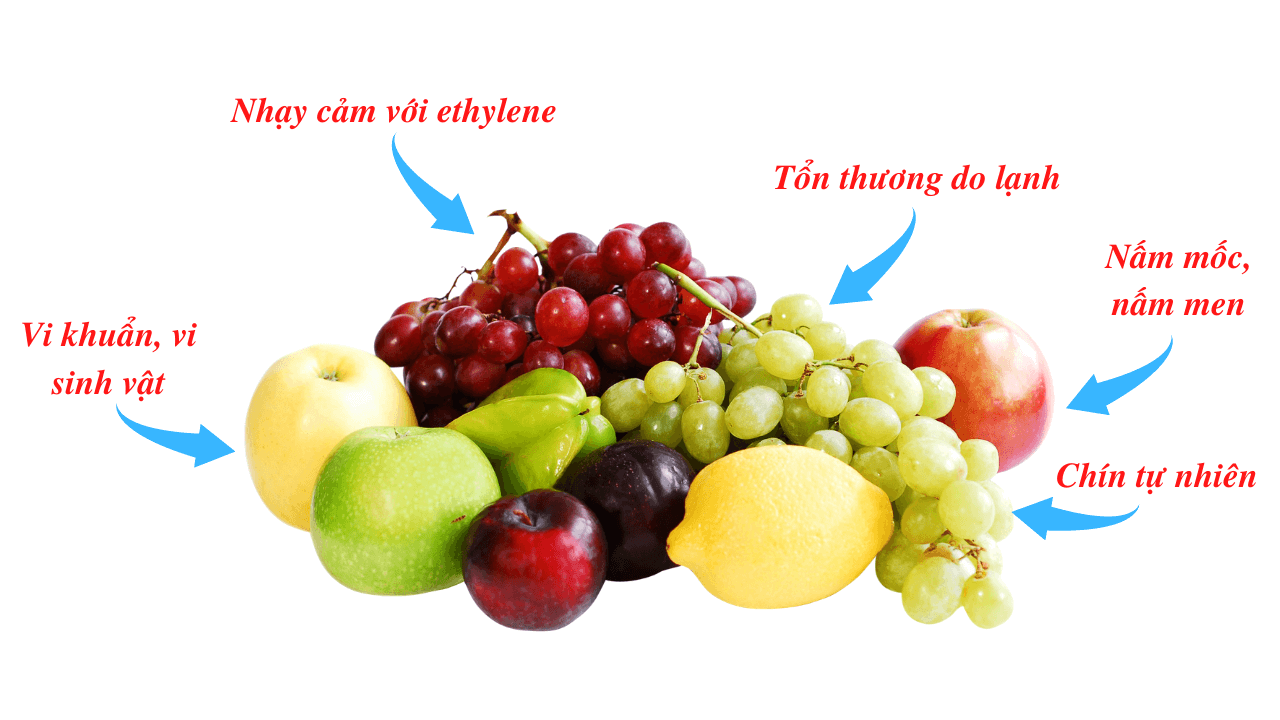

Organic products are susceptible to ethylene, mold, microorganisms, chilling injury, aging (natural ripening) , and reduced shelf life due to the lack of chemical protection.

Therefore, most organic products are transported by air, which costs 5 to 10 times more than shipping by sea.

For this reason, many companies decide not to sell organic products abroad.

Traditional Solution:

- Fungicides

- Sulfur fumigation

- Cold storage

Agricultural preservation solutions are very effective in keeping agricultural products fresh for a long time, but in return, the ingredients inside them are very harmful to human health, some of which are banned in some countries.

Therefore, finding an alternative solution to keep agricultural products fresh without harming the health of consumers. Especially ensuring full standards and quality when importing to major markets such as: Europe, America, Japan, Korea, Australia…

Therefore, in this article I would like to introduce you to how to preserve agricultural products after harvest by using the method of controlling the atmosphere in a refrigerated container, helping to maintain freshness for up to 40 days.

Fully meet the standards:

- Food safety

- No mold, yeast

- No chemical residue

- No cold injury

Introducing Equipment for Creating and Controlling Atmosphere Inside Refrigerated Containers

Technology to create, control and monitor in real time environmental factors such as: Oxygen (O2), Carbon Dioxide (CO2) and Ozone (O3), atmosphere and temperature… inside refrigerated containers helps preserve fresh agricultural products for a long time.

To optimize transportation and preserve fresh and safe agricultural products to consumers.

VTV News Reports on Atmospheric Control Equipment, Ozone Generation and Monitoring of Journey During the Transportation and Preservation of Agricultural Products

Benefits, Main Features Of Controlled Atmosphere Equipment In Agricultural Product Preservation?

Features

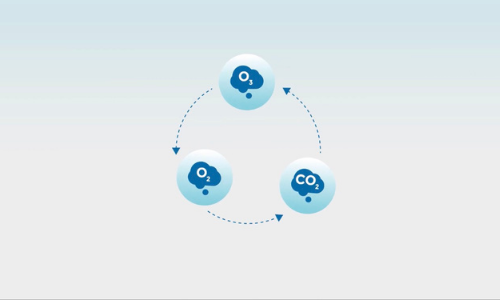

Post-harvest preservation of agricultural products by controlled atmosphere method is to increase CO2, reduce O2 and create Ozone inside cold environment.

Increase CO2, decrease O2

Vegetables and fruits stored in this environment will stop breathing and go into hibernation.

Generate O3 along the way:

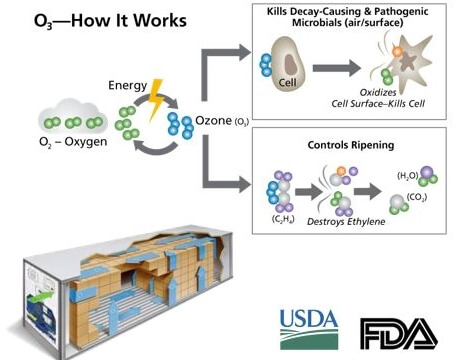

Technology to convert oxygen in the air to create Ozone gas.

Ozone Properties:

It is a strong oxidant and antibacterial agent that rapidly decomposes into oxygen (O2) after reacting with organic matter or microorganisms.

>>> See More: Top 10 Methods of Preserving Fruits and Vegetables After Harvest

Benefit

1. Benefits of Post-Harvest Agricultural Product Preservation Using Controlled Atmosphere Method

Vegetables and Fruits Stop Breathing:

Fruits and vegetables go into a state of hibernation, thereby minimizing decay, controlling the ripening process and ensuring food safety without the use of chemicals.

Video Introducing Atmosphere Control Equipment, Ozone Generation and Monitoring During The Transportation And Preservation Of Agricultural Products

2. Ozone Benefits

Ethylene Oxidation: Ozone oxidizes ethylene gas, with the reaction producing water, oxygen, and carbon dioxide.

Ozone is effective in removing ethylene build-up from produce in containers:

C2H4 + 6O3 → 2CO2 + 2H20 + 6O2

Slows Ripening: Since ethylene stimulates ripening, oxidation of ethylene with ozone will slow down the ripening and senescence process in many fruits, vegetables and flowers.

Pesticide Residue Reduction: Ozone is effective in oxidizing and reducing pesticide residues on fruits and vegetables during transportation.

Effective Antibacterial, Reduces Spoilage and Enhances Food Safety: Ozone is a powerful antibacterial and is effective against molds, yeasts, bacteria, spores, viruses (salmonella, E. coli, listeria) and parasites and other contaminants in the air and on surfaces.

It helps control these bacteria on products, hard surfaces and in the air. Ozone leaves no toxic residue, environmentally friendly.

Keeping Food Safe During Coronavirus: Ozone has been shown to kill the SARS coronavirus and since the structure of the new 2019-nCoV coronavirus is almost identical to the SARS coronavirus, it is relatively safe to say that it will also work on the new coronavirus, although it must be noted that there is only one ongoing study currently in China at the Institute of Virology in Hubei on this matter.

The progress of that research has shown that it works. Additionally, there are over 17 scientific studies showing that Ozone gas can kill the SARS coronavirus.

Mold: Ozone inhibits the germination and production of fungal spores, preventing growth and secondary spread in product containers (nesting).

Odors: Ozone reacts easily with many chemicals in the air and on surfaces and is effective in eliminating odors. This prevents cross-contamination of odors.

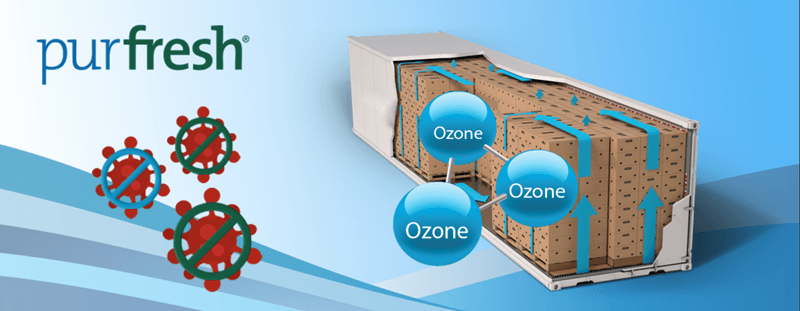

The Power of Ozone Combined with Atmospheric Control and Intellipur Monitoring Software

Ideal solution to protect perishable and ethylene sensitive goods.

Scientifically designed, with a system that enhances CO2, reduces O2 and simultaneously creates Ozone inside the refrigerated container by using oxygen from the air during transportation.

Helps control mold, yeast, Ethylene, Salmonella, E. coli, Listeria and other contaminants in the air and on surfaces.

Ozone acts as a powerful disinfectant, leaving no residue, preserving the natural taste and texture of the product.

Tracking: Equipped with Intellipur tracking and monitoring software, easily monitor and control temperature, humidity, Carbon dioxide, Oxygen and Ozone, as well as track the location of the container via GPS.

Help shippers avoid serious losses, quickly identify and handle problems to have a plan to rescue goods before it’s too late.

How to Use

Use directly installed into the air conditioning system of the refrigerated container, operating 15 minutes immediately after installation.

Easy operation and maintenance.

With smart design, does not take up cargo space inside the container, not affected by environmental factors.

Certified Products

It is the perfect agricultural preservation solution for organic products and is approved by USDA and FDA .

Ozone

1. Organic Certification

Ozone is listed in the National Organic Program (NOP) final rule, allowing its use in products labeled as organic.

2. Proven Effective At Levels Below OSHA Limits

The Federal Occupational Safety and Health Administration (OSHA) has approved Ozone as safe for workers (29 CFR 1910.1000) at effective levels.

Ozone can be detected by human smell at levels of 0.01 to 0.04 ppm (10-40 ppb).

OSHA’s exposure limit sets a threshold of 0.1ppm (100 ppb) for continuous exposure over an 8-hour period.

The short-term exposure limit is 0.3 ppm (300 ppb) for exposures of less than 15 minutes (4 times per day).

>>> See More: [Hot] Process of Preserving Mangoes After Harvest, Exported to Russia, Still Fresh and Delicious for 40 Days

Results of Using Post-Harvest Agricultural Product Preservation Method Using Controlled Atmosphere Method

‘Ozone attacks and reduces mold growth and enhances food safety.’ It can eliminate E. coli, salmonella and listeria bacteria by up to 99% without leaving residue.

Fruits and vegetables preserved with ozone for more than seven days showed significant reductions in surface fungicide and pesticide residues, resulting in reduced chemical health risks to consumers.

Ozone maintains hardness

In addition to reducing health risks, ozone also maintains the firmness of bell pepper skin.

This helps fight disease, reduces wastage, and ensures a more appealing product for consumers.

See More:

- Top 12 Best Food Preservation Methods Today

- Top 11 Methods of Preserving Fruits and Vegetables After Harvest

- AnsiP 1-MCP Agricultural Product Preservation

- GreenMAP Bags Keep Vegetables And Fruits Fresher And Longer

- How to Preserve Fresh Longan After Harvest for Up to 30 Days

- Ways to Preserve Agricultural Products After Harvest to Export Standards

- The Fastest And Easiest Way To Preserve Fruit In Business?

- Natacoat Anti-Mold Preservation For Fruits And Vegetables

- Detailed Instructions on How to Preserve Oranges Fresh for a Long Time and Safely

- Ethephon Safe Fruit Ripening Agent

- KADOZAN Biological Product (Chitosan Content 2%)

- SUPER FRESH Ethylene Absorbent Bag

- Ethylene Absorber In Cold Storage For Vegetables And Fruits

- Ethylene Absorber KIF Filter Tubes

- How to Preserve Fresh Ginger for a Long Time, Prevent Mold – Ensure Export Standards to the US and Europe

- How to Preserve Fresh Pineapple for Long-distance Export

- HOCl Solution for Preserving Fruits and Food

- How to Preserve Fresh Phalaenopsis Orchids for Long-distance Transport and Export

- Instructions on How to Harvest and Preserve Avocados to Ripen Long Effectively

HOTLINE : 028.73002579 (HCM) – 024.73002579 (Hanoi)

Get advice and order quality, reputable products at:

SAO NAM JOINT STOCK COMPANY (SANCOPACK)

Email : info@sancopack.com.vn

| ✅Preserving vegetables and fruits: | ⭐Ethylene absorption, anti-mold, sterilization, anti-dehydration. |

| ✅Effective: | ⭐Keep fresh longer, reduce damage, slow ripening & aging. |

| ✅Standard: | ⭕Food safety, US FDA |

| ✅Biological products: | ⭐ Chitosan, 1-MCP, MAP, Natamycin |

| ✅Certification: | ⭐Full quality certification. |